language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

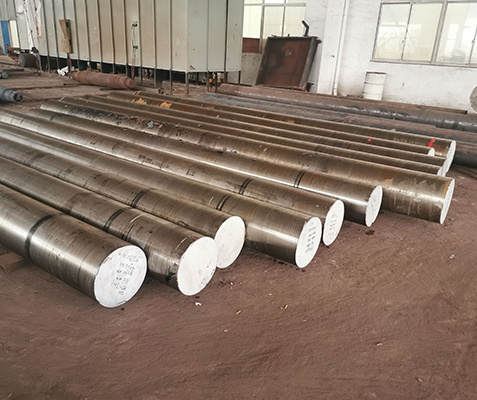

Cr12 hot rolled steel round bars

Cr12 steel is a typical alloy Tool steel, Cr12 is a chinese Cold Work Alloy Tool Steel. Its Cold work Mechanical Properties is very nice. Cr12 steel with high abrasion resistance, micro deformation of cold work die steel, the wind hard tool steel, carbon content as high as 1.5%, chromium content as high as 11.5%, the heat treatment hardness can reach 60 HRC.

VIEW MORE +

Steel grade Q345B is the most common used as high strength low alloy structural steel in industry area.Xinsteel can offer steel coils,steel plates,angles,channels for Q345B materials.The equivalent steel grade with Q345B are EN 10025-2 S355JR,ASTM A572/A572 A572 Grade 50 and DIN 17100 St52-3.

VIEW MORE +

GCr15 hot rolled steel round bars

GCr15 is a common steel which is used to produce balls and rings of bearing.GB GCr15 bearing steel is GB standard Alloy Bearing steel, It belong to the high quality high carbon, alloy chromium,manganese steel.

VIEW MORE +

Q460D hot rolled steel round bars

Q460 steel is a Chinese steel grade of Low Alloy High Strength Structural Steel, Yield Strength is 460 MPa, data is tested with 16mm diameter steel bars or steel plates, tensile strength is 550-720 Mpa, test with steel bar Ø≤40mm.For Q460 steel equivalent, chemical composition and mechanical properties, please see the tables below.

VIEW MORE +

T8-T10A hot rolled steel round bars

T8, T10 and T12 are carbon tool steels. They are very hard. The Brinell hardness in annealed state is more than 300.Manual saw blade is T12 material, just quenching, hardness is greater.10 and 20 are low carbon, high quality structural steel, very soft, Brinell hardness is less than 155.Therefore, the fitter saw, laborious, the saw is very easy to wear.

VIEW MORE +

10# hot rolled round steel bar

10# round steel is a high-quality low-carbon carbon steel, with good plasticity and toughness, easy to be formed by cold and hot processing, good cutting performance after normalizing or cold working, excellent weldability, no temper brittleness, hardenability and hardenability difference. Manufacturing parts that require low stress and high toughness, such as car bodies, receptacles, deep-drawn vessels, tubes, gaskets, etc., can be used for cold rolling, cold stamping, cold heading, cold bending, hot rolling and #other processes. It can also be used as carburizing parts and carbonitriding parts with low core strength.

VIEW MORE +