Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

ASTM A106 Black Carbon Seamless Steel Pipe

that are used in the development of gas or oil refineries, petrochemical plants, ships,

boilers and power plants.

Product Details

Product introduction

ASTM A 106 Black Carbon Seamless Steel Pipe

Standard: ASTM A106/A106M

This specification covers carbon steel pipe for high-temperature service.

Application of ASTM 106 Carbon Seamless Steel Pipe:

Pipe ordered under this specification shall be suitable for bending, flanging, and similar forming operations, and for welding.

When the steel is to be welded, it is presupposed that a welding procedure suitable to the grade of steel and intended use or service

will be utilized.

Manufacturing Process of ASTM A106 Seamless Steel Tube:

ASTM A106 seamless steel pipe are produced either by cold-drawn or hot rolled, as specified.

Hot finished pipe need not heat treated. When hot finished pipe is heat treated, it shall be heat treated at a temperature of 1200°F or higher.

Cold drawn pipe shall be heat treated after final cold draw pass at a temperature of 1200°F or higher.

Details of ASTM A106 Seamless Steel Pipe We can supply:

Manufacture:Seamless process, cold drawn or hot rolled

Cold drawn: O.D.: 15.0~100mm W.T.: 2~10mm

Hot rolled: O.D.: 25~700mm W.T.: 3~50mm

Grade: Gr.A ,Gr.B, Gr.C.

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Threaded

Mechanical and NDT Tests for ASTM A106 Black Seamless Steel Pipe

Bending Test— a sufficient length of pipe shall stand being bent cold through 90° around a cylindrical mandrel.

Flattening test-although testing is not required, pipe shall be capable of meeting the flattening test requirements.

Hydro-static test—except as allowed, each length of pipe shall be subjected to the hydro-static test without leakage through the pipe wall.

Nondestructive electric test-as an alternative to the hydro-static test, the full body of each pipe shall be tested with a nondestructive electric test.

Technical data

Chemical Composition

| ASTM A106 – ASME SA106 seamless carbon steel pipe – chemical composition, % | ||||||||||

| Element | C max |

Mn | P max |

S max |

Si min |

Cr max (3) |

Cu max (3) |

Mo max (3) |

Ni max (3) |

V max (3) |

| ASTM A106 Grade A | 0.25 (1) | 0.27-0.93 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| ASTM A106 Grade B | 0.30 (2) | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| ASTM A106 Grade C | 0.35 (2) | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

ASTM A106 Gr-B Carbon Seamless Steel Pipe Mechanical & Physical Properties

| ASTM A106 pipe | A106 Grade A | A106 Grade B | A106 Grade C |

| Tensile Strength, min., psi | 48,000 | 60,000 | 70,000 |

| Yield Strength, min., psi | 30,000 | 35,000 | 40,000 |

ASTM A106 Gr-B Carbon Seamless Steel Pipe Dimension Tolerances

| Pipe Type | Pipe Sizes | Tolerances | |

| Cold Drawn | OD | ≤48.3mm | ±0.40mm |

| ≥60.3mm | ±1%mm | ||

| WT | ±12.5% | ||

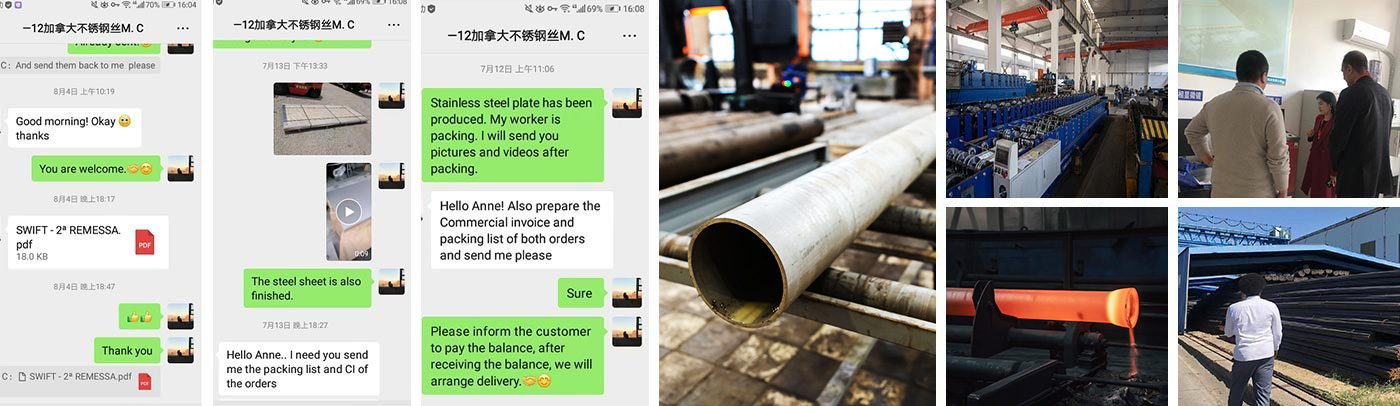

CUSTOMER TRANSACTION

Always adhere to the tenet of high quality, low cost, fast pace and excellent service. Shandong Chengshun Metal Materials Co., Ltd. is willing to cooperate sincerely with friends from all walks of life at home and abroad for common development.

STORAGE VIDEO

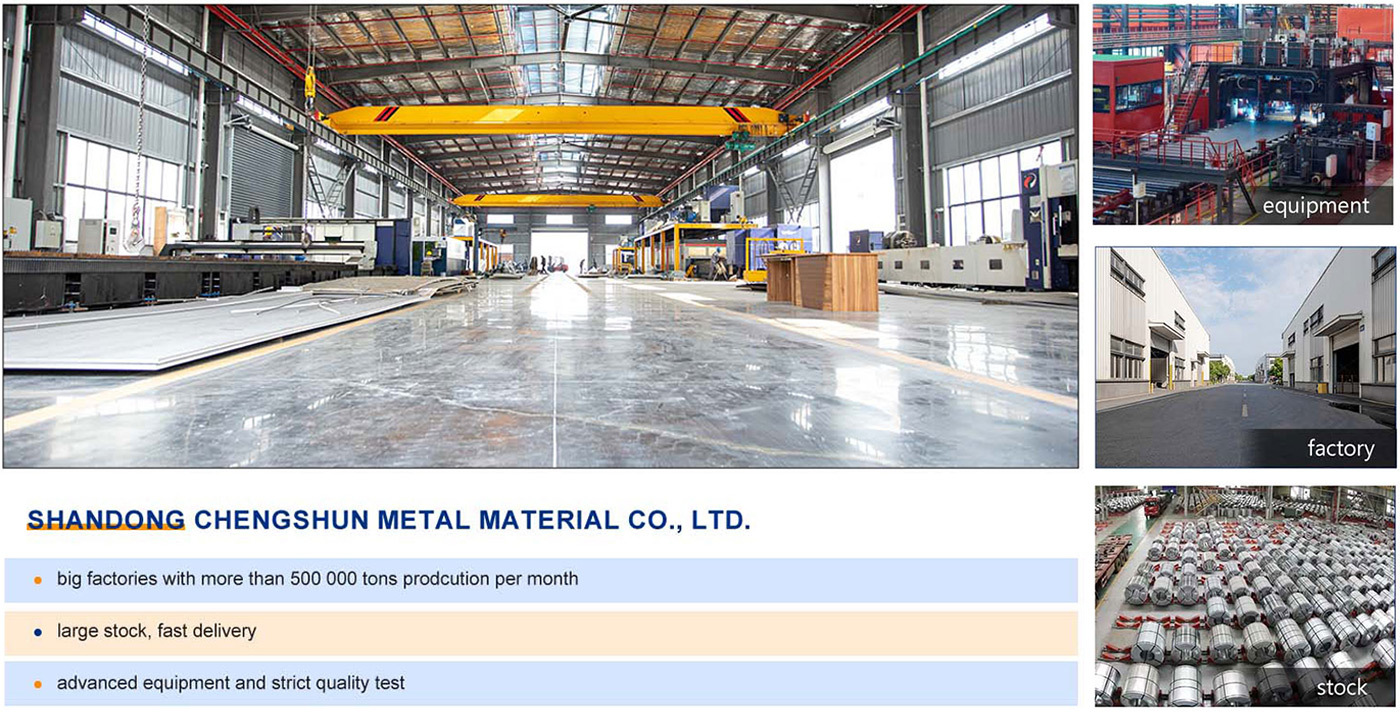

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE