Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

309 309S Hot Rolled Stainless Steel Coil

which is used for occasions requiring welding. The lower carbon

content minimizes the precipitation of carbides in the heat affected

zone near the weld, which may lead to intergranular corrosion

(welding corrosion) of stainless steel in some environments.

Product Details

201 Stainless Steel Coil Strip Specifications:

| Grades |

Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L , 309, 309S, 310, 310S, 316, 316L, 316TI, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L |

|

Thickness |

0.2mm - 60mm |

|

Width |

3.2mm - 2000mm |

|

Length |

AS PER CUSTOMER'S REQUIREMENT |

|

Type of Material |

STAINLESS STEEL SOFT, DEEP DRAW, EXTRA DEEP DRAW, QUARTER HARD, HALF HARD,FULL HARD. |

|

Finish |

NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

|

Standard |

ASME, ASTM, AISI, EN, BS, GB, DIN, JIS, SUS, etc. |

|

manufacture |

Cold Rolled ,hot rolled |

|

Application |

Decoration,Industry,food processing and medical industry ,ships building industry etc. |

|

Certification |

SGS, BV, IQI, TUV, ISO, CE, etc |

|

Coil Weight |

3-10 Tons Or As Your Requirements |

|

Tolerance |

±1% |

|

MOQ |

1 ton |

|

Supply Ability |

5000 tons / month |

|

Lead Time |

7-15 working days after the receipt of 30% deposit |

|

Payment Terms |

30%T/T Advance + 70% Balance |

|

Price Terms |

FOB, CFR, CIF, EXW |

|

Packing |

Standard sea-worthy package or as required |

Chemical Composition of 309/309S Stainless Steel Coil:

| Grade |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

|

201 |

≤0 .15 |

≤0 .75 |

5. 5-7. 5 |

≤0.06 |

≤ 0.03 |

3.5 -5.5 |

16.0 -18.0 |

- |

|

202 |

≤0 .15 |

≤L.0 |

7.5-10.0 |

≤0.06 |

≤ 0.03 |

4.0-6.0 |

17.0-19.0 |

- |

|

301 |

≤0 .15 |

≤L.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

6.0-8.0 |

16.0-18.0 |

- |

|

302 |

≤0 .15 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

8.0-10.0 |

17.0-19.0 |

- |

|

304 |

≤0 .0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

8.0-10.5 |

18.0-20.0 |

- |

|

304L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

9.0-13.0 |

18.0-20.0 |

- |

|

309S |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

12.0-15.0 |

22.0-24.0 |

- |

|

310S |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.035 |

≤ 0.03 |

19.0-22.0 |

24.0-26.0 |

|

|

316 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

|

316L |

≤0 .03 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

12.0 -15.0 |

16 .0 -1 8.0 |

2.0 -3.0 |

|

321 |

≤ 0 .08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

9.0 - 13 .0 |

17.0 -1 9.0 |

- |

|

630 |

≤ 0 .07 |

≤1.0 |

≤1.0 |

≤0.035 |

≤ 0.03 |

3.0-5.0 |

15.5-17.5 |

- |

|

631 |

≤0.09 |

≤1.0 |

≤1.0 |

≤0.030 |

≤0.035 |

6.50-7.75 |

16.0-18.0 |

- |

|

904L |

≤ 2 .0 |

≤0.045 |

≤1.0 |

≤0.035 |

- |

23.0·28.0 |

19.0-23.0 |

4.0-5.0 |

|

2205 |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.030 |

≤0.02 |

4.5-6.5 |

22.0-23.0 |

3.0-3.5 |

|

2507 |

≤0.03 |

≤0.8 |

≤1.2 |

≤0.035 |

≤0.02 |

6.0-8.0 |

24.0-26.0 |

3.0-5.0 |

|

2520 |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.045 |

≤ 0.03 |

0.19 -0. 22 |

0. 24 -0 . 26 |

- |

|

410 |

≤0.15 |

≤1.0 |

≤1.0 |

≤0.035 |

≤ 0.03 |

- |

11.5-13.5 |

- |

|

430 |

≤0.1 2 |

≤0.75 |

≤1.0 |

≤ 0.040 |

≤ 0.03 |

≤0.60 |

16.0 -18.0 |

- |

201 stainless steel coil is mainly used as decorative pipe, industrial pipe and some shallow stretched products.201 stainless steel coil is mainly used for high temperature applications. High temperature applications require strong sensitization resistance to prevent intergranular corrosion at lower temperatures.

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

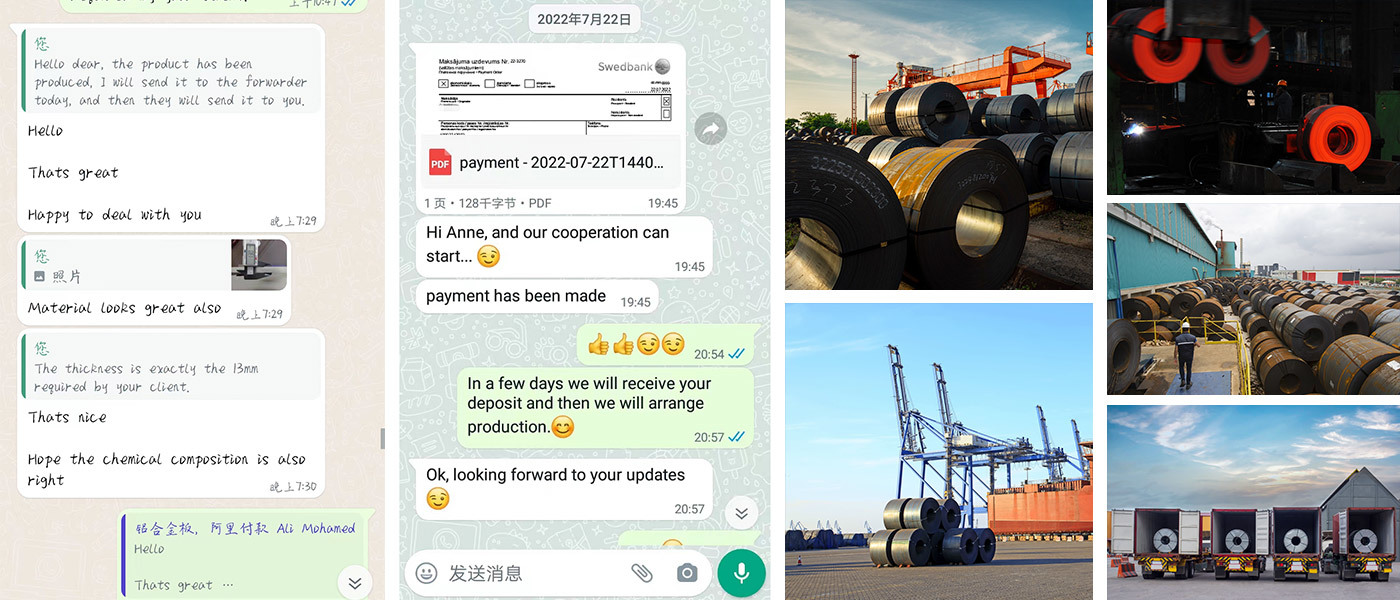

CUSTOMER TRANSACTION

Always adhere to the tenet of high quality, low cost, fast pace and excellent service. Shandong Chengshun Metal Materials Co., Ltd. is willing to cooperate sincerely with friends from all walks of life at home and abroad for common development.

STORAGE VIDEO

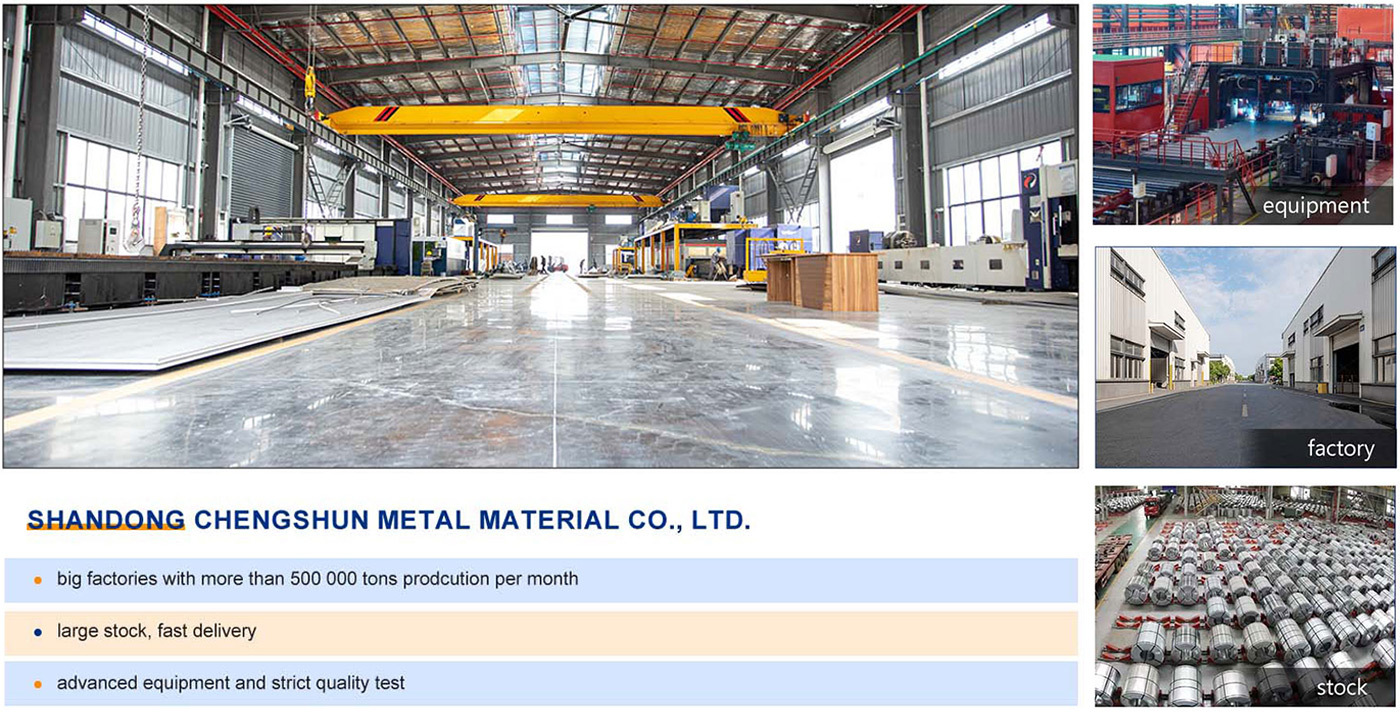

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

Packing and shipping

Mainly exported to Europe, Southeast Asia, South Africa, the Middle East, Latin America and other countries and regions, the products are favored by Chinese and foreign users.

product display

Application field

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE