Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

T8-T10A hot rolled steel round bars

Product Details

T8-T10A hot rolled steel round bars information

Tool steels are high quality steels developed with controlled chemical composition to form properties essential for working and shaping of other materials. They are normally delivered to the suppliers in the soft annealed condition, which makes it easy for the manufacturer to machine the material with cutting tool for different applications.AISI T8 tool steel is a tungsten-cobalt-vanadium high-speed tool steel. The following datasheet will provide an overview of grade T8 tool steels.

Chemical and Mechanical

Chemical Composition

The chemical composition of T8 tool steels is outlined in the following table.

| Element | Content (%) |

|---|---|

| Tungsten, W | 13.25-14.75 |

| Cobalt, Co | 4.25-5.75 |

| Chromium, Cr | 3.75-4.5 |

| Vanadium, V | 1.80-2.40 |

| Carbon, C | 0.75-0.85 |

| Molybdenum, Mo | 0.4-1 |

| Nickel, Ni | 0.3 |

| Copper, Cu | 0.25 |

| Manganese, Mn | 0.2-0.4 |

| Silicon, Si | 0.2-0.4 |

| Phosphorus, P | 0.03 |

| Sulfur, S | 0.03 |

Physical Properties

The following table shows the physical properties of T8 tool steels.

| Properties | Metric | Imperial |

|---|---|---|

| Density | 8.43 g/cm3 | 0.267 lb/in3 |

Mechanical Properties

The mechanical properties of T8 tool steels are displayed in the following table.

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 1158 MPa | 167.95 ksi |

| Elongation | 15% | 15% |

| Modulus of elasticity | 190-210 GPa | 27557- 30457 ksi |

| Poisson’s ratio | 0.27-0.3 | 0.27-0.3 |

Thermal Properties

The thermal properties of T8 tool steels are given in the following table

| Properties | Metric | Imperial |

|---|---|---|

| Thermal expansion co-efficient | 16-17 µm/m°C | 8.8-9.4 µin/in°F |

| Thermal conductivity | 16 W/mK | 110 BTU.in/hrft².°F |

T8 Range of products

| Product type | Products | Dimension | Processes | Deliver Status |

|---|---|---|---|---|

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

Cross Reference Table(Equivalent Grade

| Grade | Standard | Country | Application |

|---|---|---|---|

| T8 | ASTM | USA | High-Speed Tool Steel |

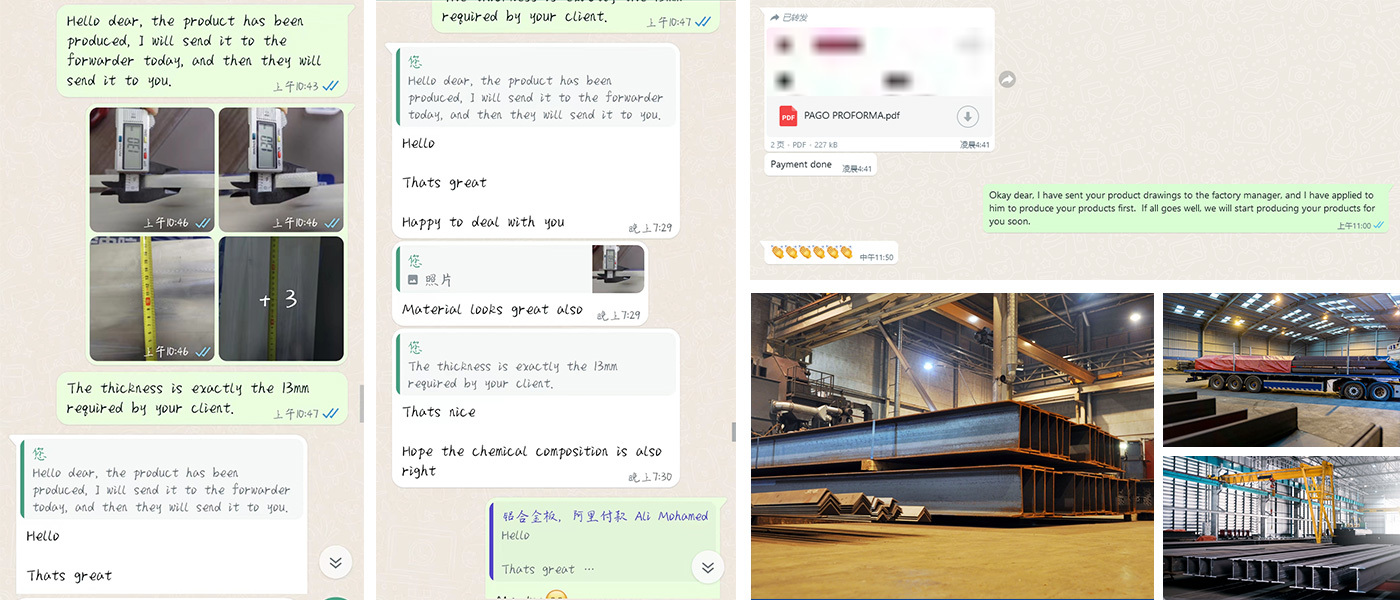

CUSTOMER TRANSACTION

STORAGE VIDEO

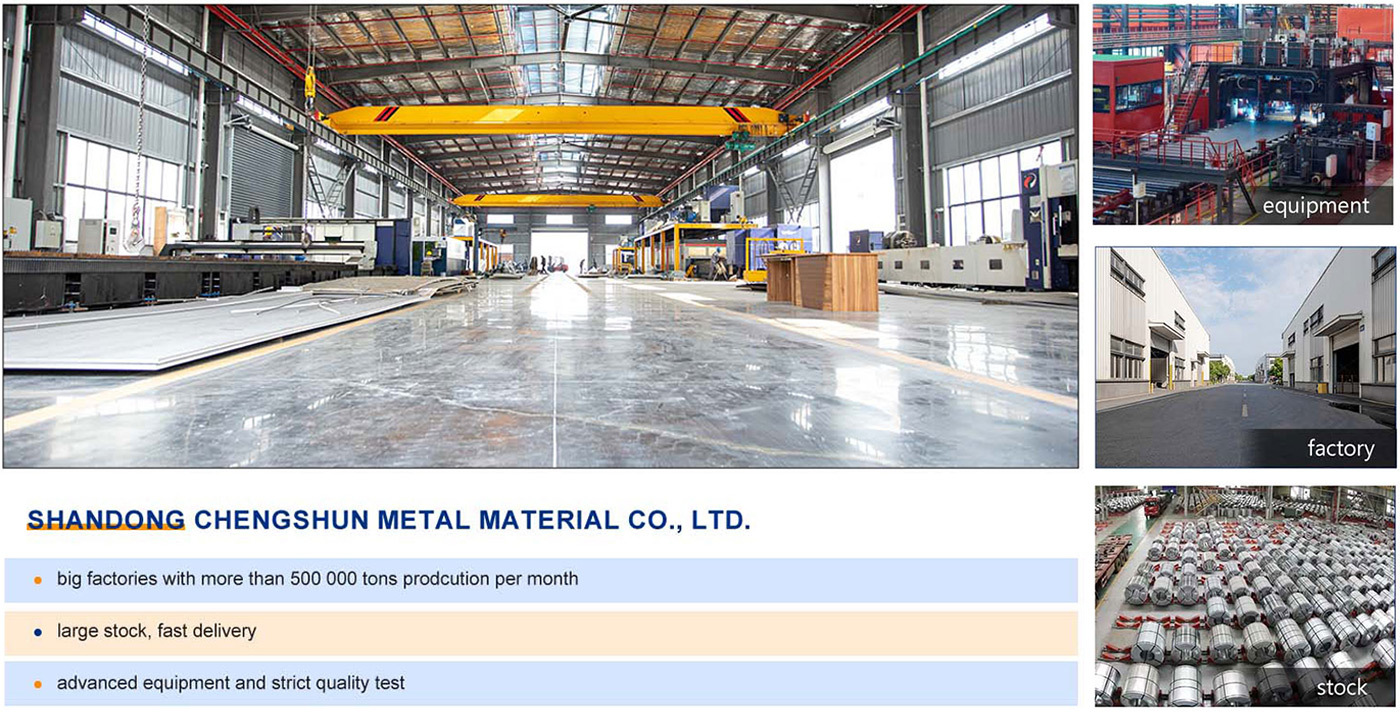

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE