Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

45# hot rolled steel sheet

Product Details

Product introduction

The recommended heat treatment system for 45 steel specified in the GB/T699-1999 standard is normalizing at 850°C, quenching at 840°C, and tempering at 600°C. The achieved performance is yield strength ≥355MPa

The GB/T699-1999 standard stipulates that the tensile strength of 45 steel is 600MPa, the yield strength is 355MPa, the elongation rate is 16%, and the reduction of area is 40%.

Application

No. 45 steel is widely used in machinery, when it is not heat treated: HB≤229; heat treatment: normalizing; impact energy: Aku≥39J; high strength, good plasticity and toughness, 45# steel plate after quenching without tempering, the hardness is greater than HRC55 (Up to HRC62) is qualified. After heat treatment and tempering, it can reach HRC42-46, which can not only ensure its good mechanical properties, but also obtain the hardness requirements of the surface. It is used to make small section adjustments that can withstand larger loads. Quality parts and large normalized parts with less stress, as well as surface hardened parts that do not require high core strength, such as tips, guide posts, watch hands and other components.

Product parameters

| Material: | forged square steel bar |

| Diameter: | 100mm-1000mm |

| Length: | 2000mm-12000mm Straightness: 3mm/M max; square bar.100-1000mm, blocks sizes up to 800*1000mm |

| Process: | EAF + LF + VD + Forged + Heat Treatment (optional) |

| Delivery condition: | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) |

| Delivery Time: | 30-45 days |

| MOQ: | 20 tons |

| Heat treatment: | Normalized / Annealed / Quenched / tempered |

| Forged ratio: | no less than 3:1 |

| Technical Data: | According to the customer's requirement of Chemical Composition, Physical Properties and Mechanical Testing |

| Test: | Ultrasonic test according to SEP 1921-84 G3 C/c |

| Marking: | Grade, heat NO. length will be stamped one each bar with required color |

| Payment: | 30% advance by TT; Balance pay before the shipment against shipping documents or irrevocable LC at sight |

| Application: | Statically and dynamically stressed components for vehicles, engines and machines. For parts of larger cross-sections, crankshafts, gears. |

Technical data

| Grade | Dia(mm) | C | Si | Mn | P | S | Ni | Cu | Cr |

| 20 | 18-600 |

0.17-0.23 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.30 | ≤0.25 | ≤0.25 |

| 45 | 20-600 | 0.42-0.50 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.30 | ≤0.25 | ≤0.25 |

Mechanical properties

| Yield strength σs/MPa (>=) | Tensile strength σb/MPa (>=) | Elongation δ5/% (>=) |

Reduction of area ψ/% (>=) |

Hardness HBS |

| ≥355 | ≥600 | ≥16 | ≥40 | ≤197 |

Features of C45 steel

1, Medium carbon structural steel

2, High strength and machinability

3, Good toughness, plasticity and abrasion resistance

4, Typically used in quenched and tempered or normalized conditions

4,Typical Applications

1, Widely used in machine manufacturing

2, For shaft parts

3, Stamping die drawing parts repair and hardfacing

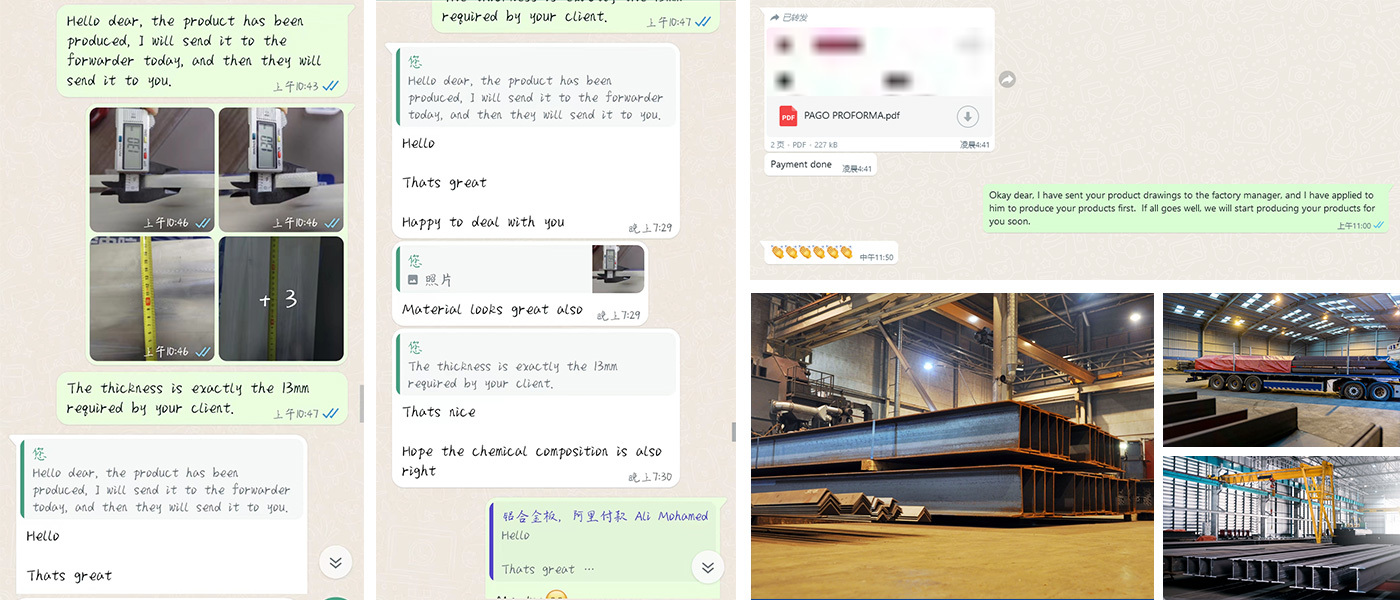

CUSTOMER TRANSACTION

STORAGE VIDEO

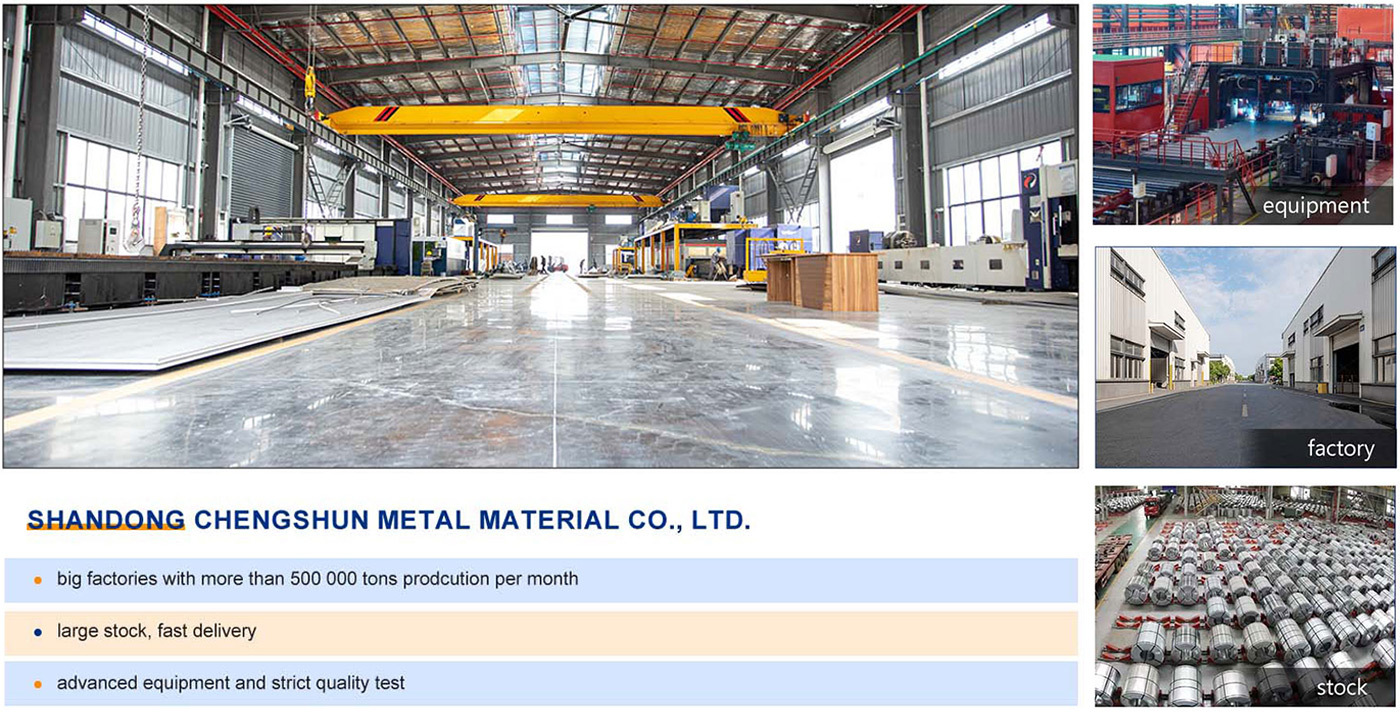

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE