Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

20CrMo hot rolled steel sheet

Product Details

Product introduction

steel round bars are widely used in machinery making, autombile making, railway, mine machinery, petoleum machinry, agricultural machinery and civil archtectue such as all kinds of shafts, screws, connecting rods, hardware tools, gears, standard parts, spanners fasteners, structural parts for automobile and agricultural machinery, outer and iner sleeves, rollers and balls for bearing making.

GB 20CrMo steel is a kind of Chinese alloy steel for engineering and mechanical structure purpose, which is generally used in quenching or tempering or carburizing and quenching. 20CrMo material has high heat strength, good hardenability, no temper brittleness, cold strain plasticity, good machinability and weldability.

Technical data

20crmo Alloy Steel Bar Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 20CrMo | 0.17-0.24 | 0.17-0.37 | 0.40-0.70 | ≤0.030 | ≤0.030 | 0.80-1.10 | 0.15-0.25 |

Mechanical Property:

| Tensile strength σb (MPa) |

Yield Strength σs 0.2 (MPa) |

Elongation δ 5 (%) |

Reduction of crosssection area ψ (%) |

Ballistic work Akv (J) |

Pounding toughness value αkv (J/cm2) |

Hardness (HB) | Specimen Size |

| Min 835 | Min 540 | Min 10 | Min 40 | Min 47 | Min 59 | Max 179 | 15mm |

Applications

20CrMo alloy steel is used in the manufacture of non-corrosive media in chemical equipment and high pressure pipes, fasteners, steam turbines, boiler blades and forgings with working temperature below 250 °C, and important carburizing parts such as gears and shafts in general machines. It can also be used in place of 1Cr13 steel to manufacture medium pressure, low pressure steam turbines in the superheated steam zone pressure stage working blades.

Heat Treatment Specification

- First quenching heating temperature: 880 °C (Quenching agent: water, oil)

- Tempering heating temperature: 500 °C (agent – water, oil)

Equivalent Grades

20CrMo material equivalent to US ASTM, European Germany DIN EN, British BS EN, France NF EN, Japanese JIS, and ISO standard. (For reference)

| 20CrMo steel equivalent | |||||||||||||

| China | USA | Germany | Japan | France | UK | ISO | |||||||

| Standard | Grade | Standard | Grade | Standard | Grade (Steel Number) | Standard | Grade | Standard | Grade (Steel Number) | Standard | Grade (Steel Number) | Standard | Grade |

| GB/T 3077 | 20CrMo | AISI SAE; ASTM A29/A29M |

4120 | DIN EN 10083-3 | 25CrMo4 (1.7218) | JIS G4053 | SCM420 | NF EN 10083-3, NF A35-551 |

25CrMo4 (1.7218), 18CD4 |

BS EN 10083-3, BS 970 Part 1 |

25CrMo4 (1.7218), 708M20 |

ISO 683-1 | 18CrMo4 |

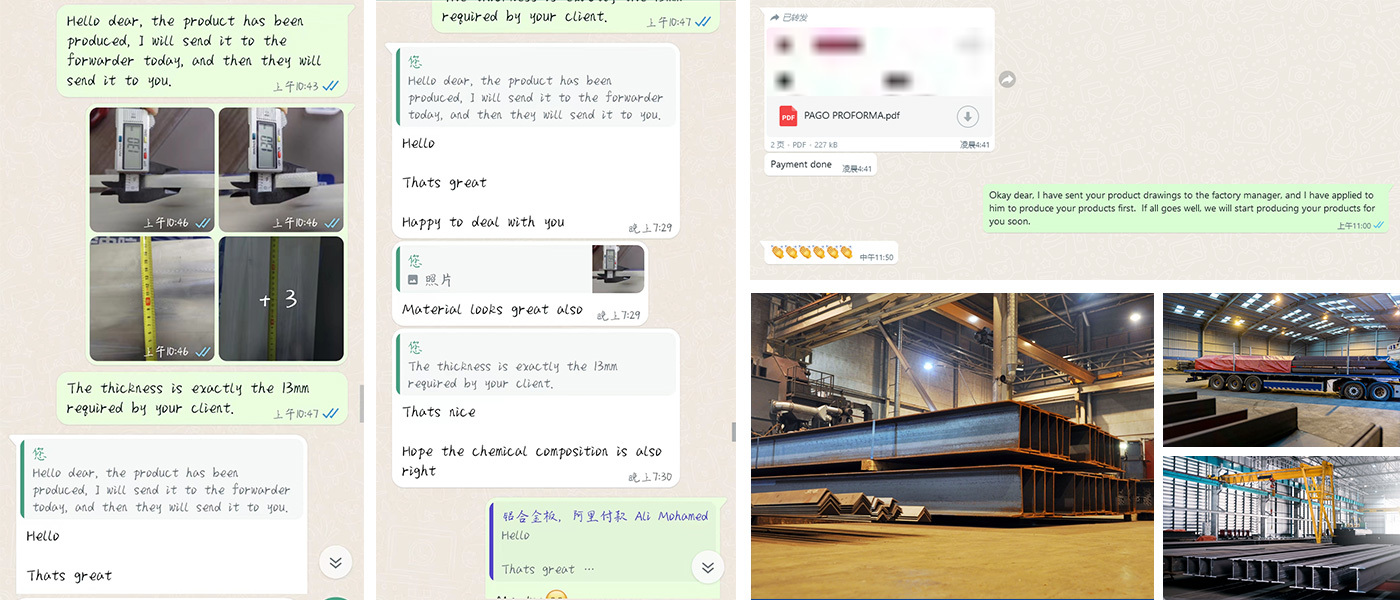

CUSTOMER TRANSACTION

STORAGE VIDEO

Factory Appearance

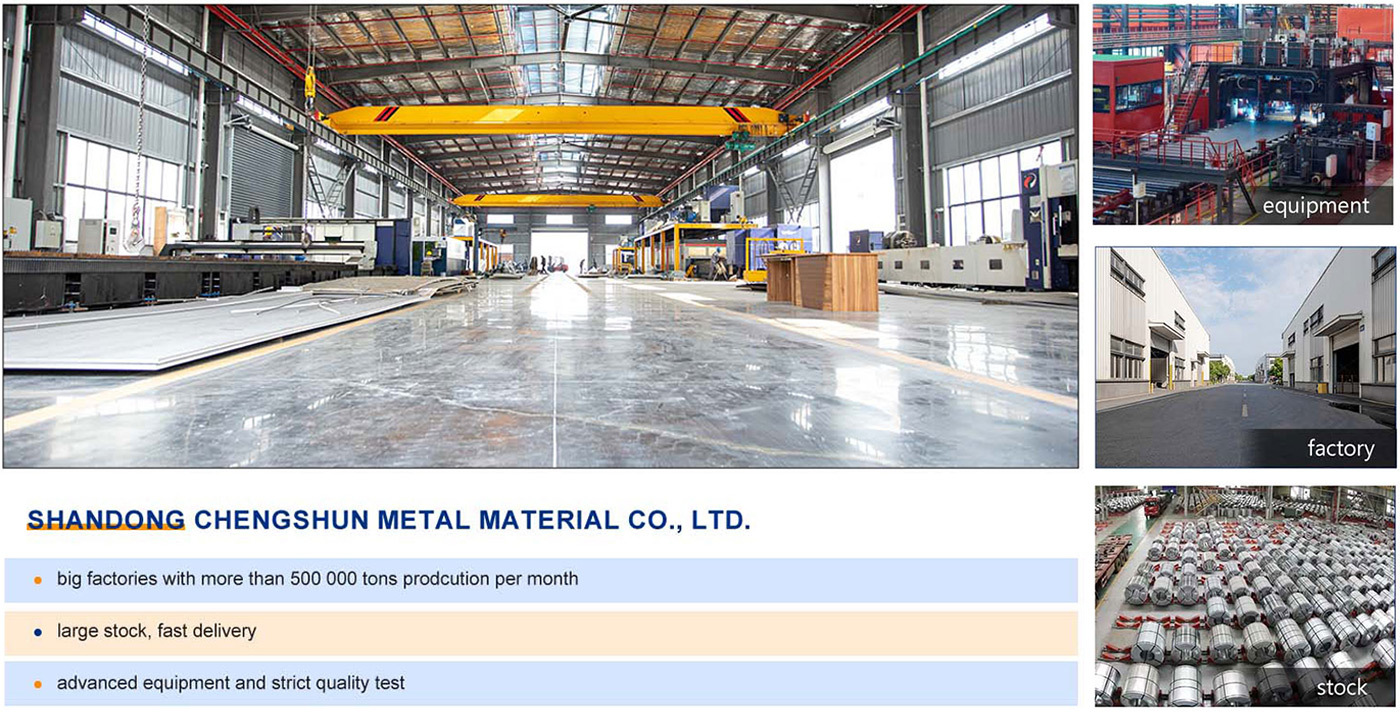

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE