Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

15CrMo hot rolled steel sheet

Product Details

Product introduction

15CrMo Structural Steel Bar ● Product Name: Alloy structural steel ● Steel: 15CrMo ● Digital Code: A30152 ● Steel Group Series: CrMo ● Implementation of the standards: GB / T3077-1999 ● Delivery status: hot-rolled or annealed, the specific delivery status should be indicated in the warranty book. ● 15CrMo features: Low-alloy heat-resistant steel, stronger than 12CrMo steel, toughness slightly lower, at 500-550 ° C or less have a higher heat resistance and oxidation resistance, and good mechanical properties, machinability and cold strain plasticity good weldability fair. Mainly used for the production of various caliber seamless steel pipe and sheet. 15CrMo Applications: Main steam pipe for steam parameters of 510 ° C, 530 ° C steam parameters of boiler superheater tubes, catheters and high-pressure steam header, after quenching and tempering, at room temperature can be used to manufacture a variety of important parts of the work.

Technical data

| Chemical Composition (%) | |||||||||

| C | Mn | Si | Cr | Mo | Ni | Nb+Ta | S | P | |

| 15CrMo | 0.12~0.18 | 0.40~0.70 | 0.17~0.37 | 0.80~1.10 | 0.40~0.55 | ≤0.30 | _ | ≤0.035 | ≤0.035 |

Mechanical properties

| Yield strength σs/MPa (>=) | Tensile strength σb/MPa (>=) | Elongation δ5/% (>=) | |

| 15CrMo | 440~640 | 235 | 21 |

Steel Material equivalent of SCM415

| USA | Germany | China | Japan | France | England | Italy | Poland | Czechia | Austria | Sweden | Spain |

| SAE/AISI/UNS | DIN,WNr | GB | JIS | AFNOR | BS | UNI | PN | CSN | ONORM | SS | UNE |

| 15CrMO | 1.7262 | 15CrMo | SCM415 | 15CD4.05 | 1501-620 | Cr31 | X30WCRV93KU |

Heat treatment is an extremely effective measure to improve and modify the properties of 15CrMo alloy round steel. It plays a very important role in product reliability and economy. The heat treatment of 15CrMo alloy round steel usually includes ordinary heat treatment (annealing, normalizing, quenching, tempering) and surface heat treatment (surface quenching and chemical heat treatment—carburizing, nitriding, metalizing, etc.).

In mechanical engineering, many machine parts, such as crankshafts, gears, camshafts of internal combustion engines, and gears in important reducers, not only require sufficient toughness, plasticity and bending strength in the core, but also require high surface thickness within a certain thickness. Hardness, high wear resistance and high fatigue strength. The aforementioned various overall heat treatment methods are difficult to meet the above performance requirements at the same time, and the use of surface heat treatment is the most effective method to achieve these performance requirements at the same time.

Surface heat treatment is a heat treatment method that changes the surface properties of 15CrMo alloy round steel by changing the structure of the surface layer.

Surface quenching is a heat treatment that changes the surface structure one by one without changing the chemical composition of the surface. It can be realized by high frequency, medium frequency or power frequency current induction heating method or flame heating method. The common feature is that the surface of the 15CrMo alloy round steel is quickly heated to the quenching temperature, and when the heat is not transferred to the core of the part, it is cooled quickly, so that the surface hardness is high, but the core still has high toughness.

Chemical treatment is a heat treatment method that changes the chemical composition and structure of the surface layer of 15CrMo alloy round steel. Chemical heat treatment can be divided into methods such as carburizing, nitriding, carbonitriding, and metalizing according to the different elements infiltrated on the surface of 15CrMo alloy round steel. It is very effective for improving and improving the wear resistance, corrosion resistance and fatigue resistance of 15CrMo alloy round steel. At present, chemical heat treatment has developed rapidly, and there are many applications of new technologies.

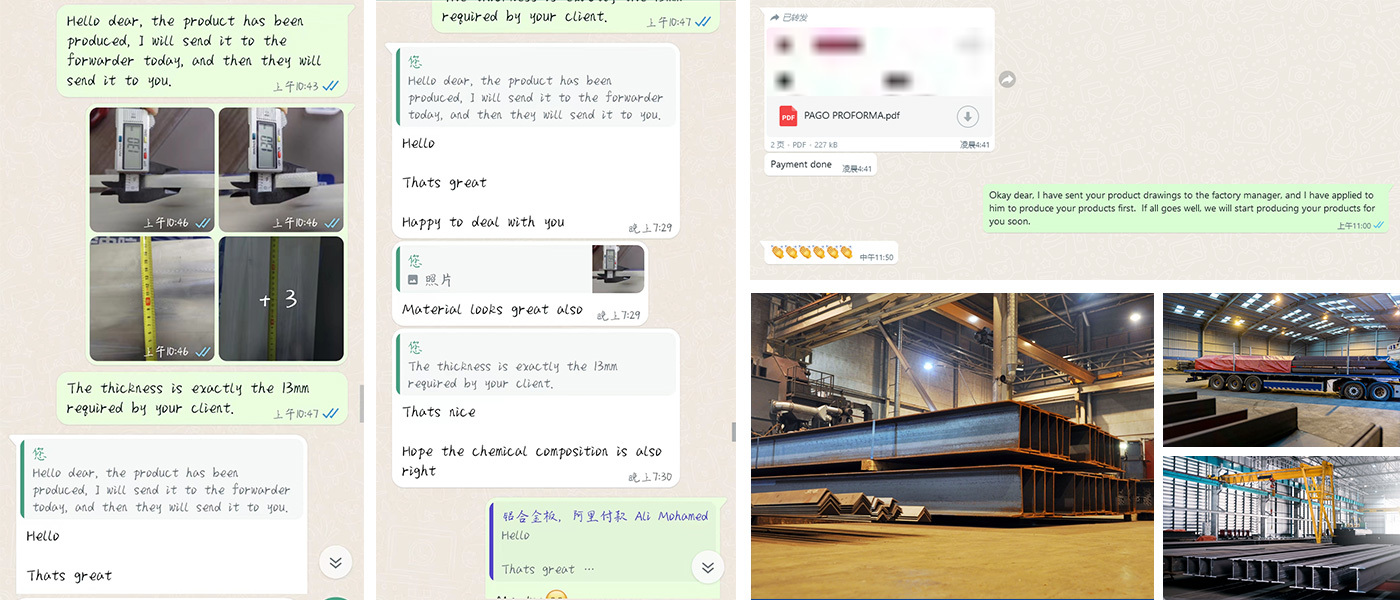

CUSTOMER TRANSACTION

STORAGE VIDEO

Factory Appearance

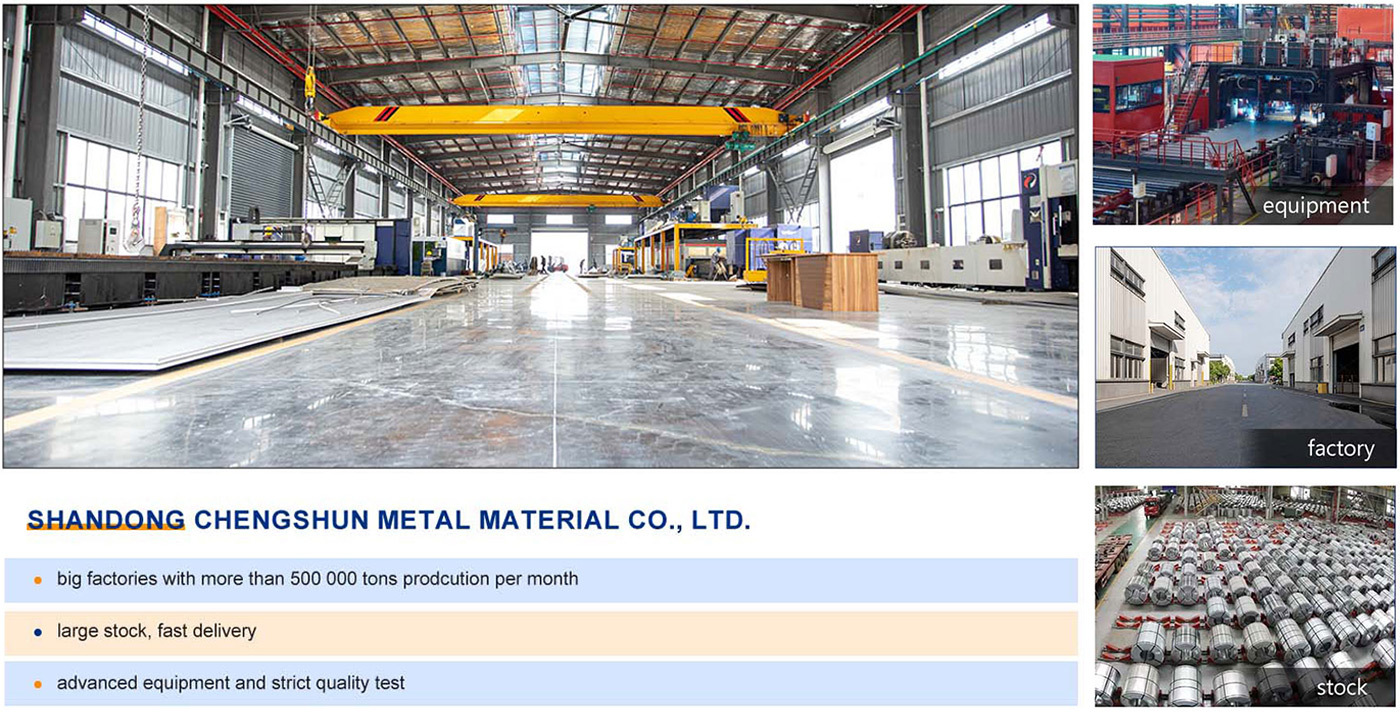

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE