Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

W6Mo5Cr4V2(M2) hot rolled steel round bars

Product Details

Product introduction

M2 is molybdenum series high-speed steel, has the advantages of small carbide inhomogeneity and high toughness. Easy to overheating, should strictly control the quenching heating temperature, the more strict protection for heat treatment. Because of its hardness and wearability, used in the manufacture of cutting more difficult to cutting tool materials. M2 high-speed steel with carbide orientation is bigger, so the more strict protection for heat treatment is suitable for the mold vibration and shock loads.

Technical data

Similar Grade

| Execution Standard | ZEICIN Grade | GB | AISI | JIS | DIN |

|---|---|---|---|---|---|

| GB/T9943-2008 | M2 | W6Mo5Cr4V2 | M2 | SKH51 | 1.3343 |

Chemical Composition of M2 Tool Steel Material

| ASTM A681 | C | Si | Mn | P | S | Cr | Mo | V | W |

| M2/ T11302 | 0.78~0.88 | 0.20~0.45 | 0.15~0.40 | 0.030 Max | 0.030 Max | 3.75~4.50 | 4.50~5.50 | 1.75~2.20 | 5.50~6.75 |

| DIN 17350 | C | Si | Mn | P | S | Cr | Mo | V | W |

| 1.3343/ S6-5-2 | 0.86~0.94 | ≤0.45 | ≤0.40 | 0.030 Max | 0.030 Max | 3.80~4.50 | 4.70~5.20 | 1.70~2.00 | 6.00~6.70 |

| GB/T 9943 | C | Si | Mn | P | S | Cr | Mo | V | W |

| W6Mo5Cr4V2 | 0.80~0.90 | 0.20~0.45 | 0.15~0.40 | 0.030 Max | 0.030 Max | 3.80~4.40 | 4.50~5.50 | 1.75~2.20 | 5.50~6.75 |

| JIS G4403 | C | Si | Mn | P | S | Cr | Mo | V | W |

| SKH51/SKH9 | 0.80~0.88 | ≤0.45 | ≤0.40 | 0.030 Max | 0.030 Max | 3.80~4.50 | 4.70~5.20 | 5.90~6.70 | 1.70~2.10 |

SAE M2 Tool Steel Material Mechanical Properties

Hardness, Rockwell C (tempered at 621°C, quenched at 1204°C): 62 HRC.

Hardness, Rockwell C (quenched at 1204°C) ): 65 HRC

Forged of M2 HSS Steel metal material

At first, Pre-Heating to 650-750℃,Then heat to forged temperature. Soak at 1204°C, ensure heat thorough. Then start forged, the forged temperature no low than 950℃. After forging, cool slowly.

Heat Treatment of SAE M2 Steel

- M2 HSS Steel Annealing

At first, Slowly heat to 871℃,then slowly Cool to 538℃(1000℉) in heat treatment furnace. Then cool in air. After annealing hardness HBS: 255 Max.

- M2 tool Steel Hardening

M2 steel having very high hardenability and should be hardened by cooling in still air. The use of a salt bath or controlled atmosphere furnace is desirable to minimize decarburization, and if not available, pack hardening in spent pitch coke is suggested.

- Quenching of HSS M2 Steel material

Quenching temperature / ℃ | salt bath furnace: 1204

Quenching temperature / ℃ | controlled atmosphere furnace: 1216

The heat preservation time/min: 5 ~ 15

Quenching medium: Oil cooling

Hardness: 65 HRc Min

- Tempering Of HSS M2 Tool Steel

Tempering temperature / ℃ : 540-564

After tempering hardness HRC or higher: 65 Min

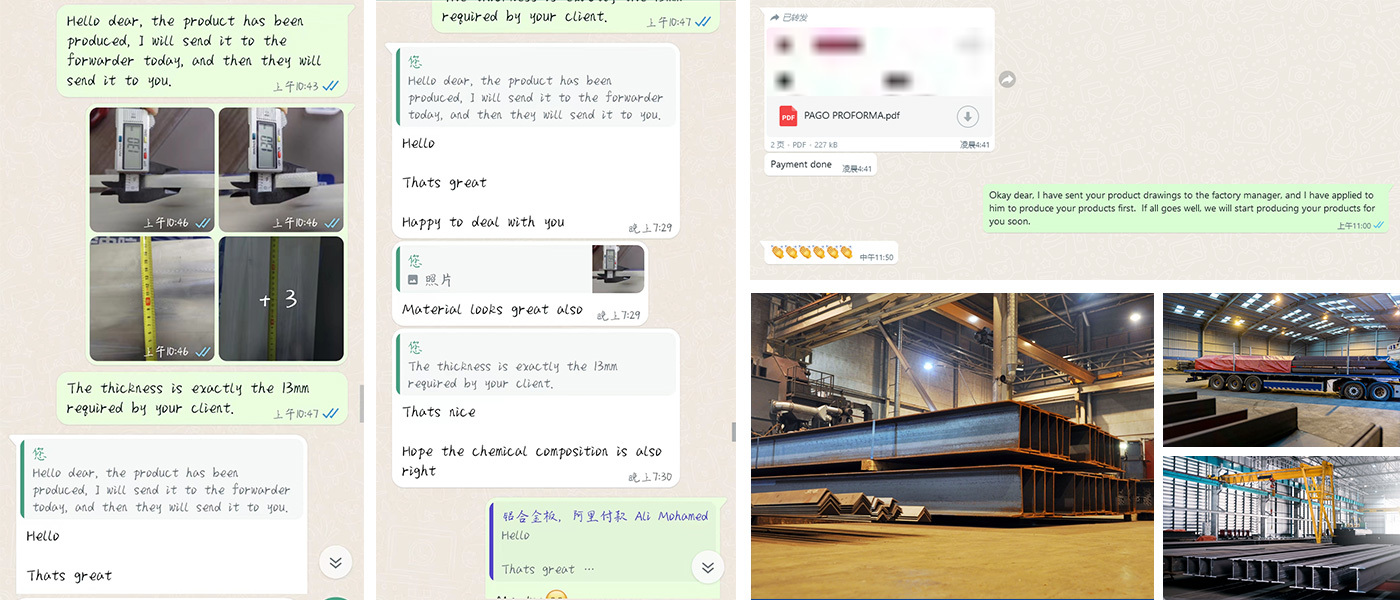

CUSTOMER TRANSACTION

STORAGE VIDEO

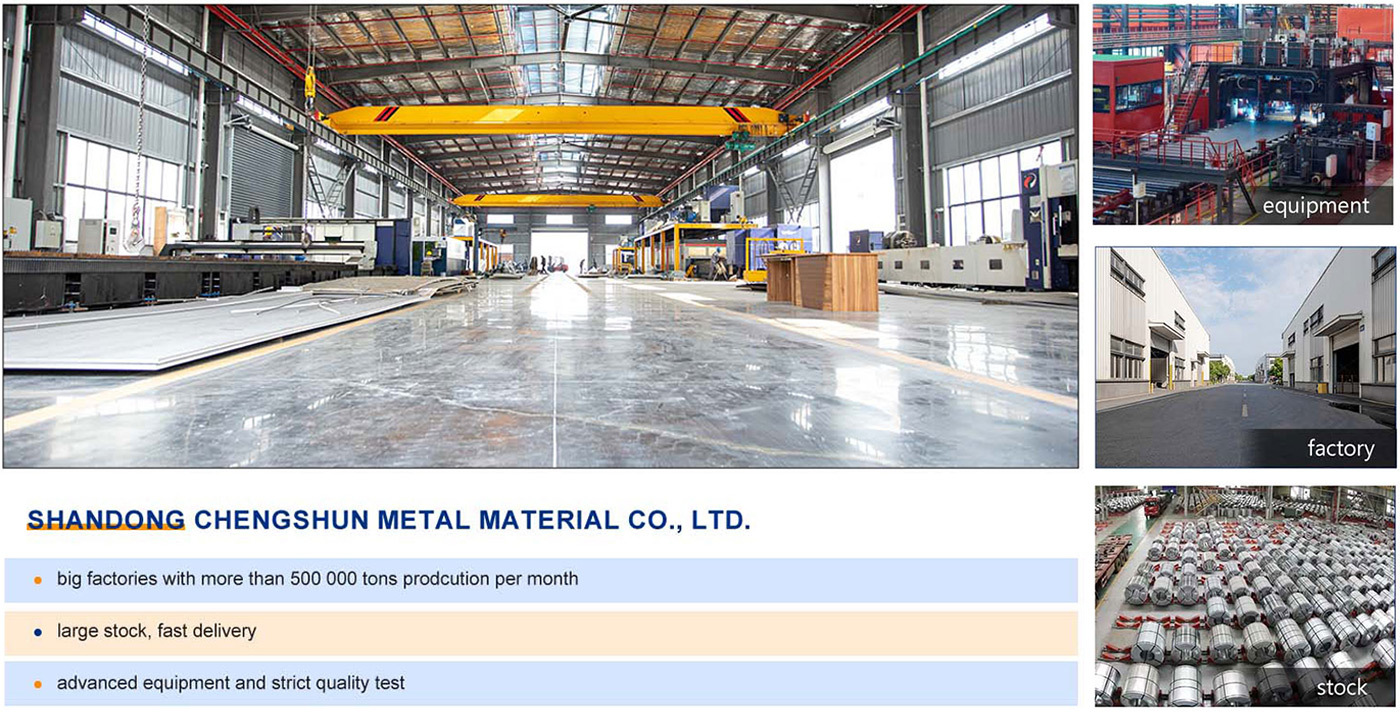

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE