Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

20CrMnTi(H) hot rolled steel round bars

Product Details

Product introduction

characteristics of hardened steel alloy tool steel, good carburizing heat treatment process and the performance of the steel at ≤960 ℃ fine grain structure, commonly used in long-term heating carburizing temperature, the grain grew no tendency little residual austenite after quenching, therefore, the steel has high strength and wear resistance, excellent cutting performance, the main performance and 20CrMnTi and 20CrNi steel similar. Tensile strength σ ≥1080MPa, yield strength σ ≥885MPa, elongation δ ≥10%, 45% reduction of swelling, impact toughness (impact toughness) α ≥69J / cm, hardness ≤207HB, blank sample size to 15mm.

Technical data

GB 20CrMnTi GB/T 3077 Mechanical

The mechanical properties of GB 20CrMnTi GB/T 3077 metals determine the range of usefulness of a material and establish the service life that can be expected. Mechanical properties are also used to help classify and identify material.

| Yield Rp0.2 (MPa) |

Tensile Rm (MPa) |

Impact KV/Ku (J) |

Elongation A (%) |

Reduction in cross section on fracture Z (%) |

As-Heat-Treated Condition | Brinell hardness (HBW) |

|---|---|---|---|---|---|---|

| 912 (≥) | 863 (≥) | 23 | 33 | 44 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 212 |

Physical performance parameters of GB 20CrMnTi GB/T 3077 are mainly indicated by density, poisson's ratio, thermal conductivity, specific thermal capacity, coefficient of thermal expansion, modulus of elasticity, electrical resistance value, etc.

| Temperature (°C) |

Modulus of elasticity (GPa) |

Mean coefficient of thermal expansion 10-6/(°C) between 20(°C) and |

Thermal conductivity (W/m·°C) |

Specific thermal capacity (J/kg·°C) |

Specific electrical resistivity (Ω mm²/m) |

Density (kg/dm³) |

Poisson’s coefficient, ν |

|---|---|---|---|---|---|---|---|

| 24 | - | - | 0.31 | - | |||

| 956 | 121 | - | 12.3 | 423 | - | ||

| 659 | - | 41 | 11.2 | 243 | 423 |

Heat treatment Related

- Annealing of 20CrMnTi Alloy Gearing steel

Slowly heated to 790-810 ℃ and allow enough times, let the steel to be thoroughly heated, Then cool slowly in the furnace. Different annealing ways will get different hardness.The 20CrMnTi Gearing steel will get Hardness MAX 248 HB (Brinell hardness).

- Quenching and temperature of 20CrMnTi gear steel

Heated slowly to 788°C, Then put in salt-bath furnace keep 1191 ℃to 1204 ℃。quenching by oil get 60 to 66 HRc hardness. High temperature tempering: 650-700℃,cool in air, get hardness 22 to 30HRC. Low temperature tempering: 150-200 ℃, Cool in ari, get 61-66HRC hardness.

- Hot work and cold work of 20CrMnTi Alloy Gearing steel

GB 20CrMnTi steel can hot worked at 205 to 538°C, 20CrMnTi Bearing/Gearing steel can be cold worked using conventional techniques in the annealed or normalized conditions.

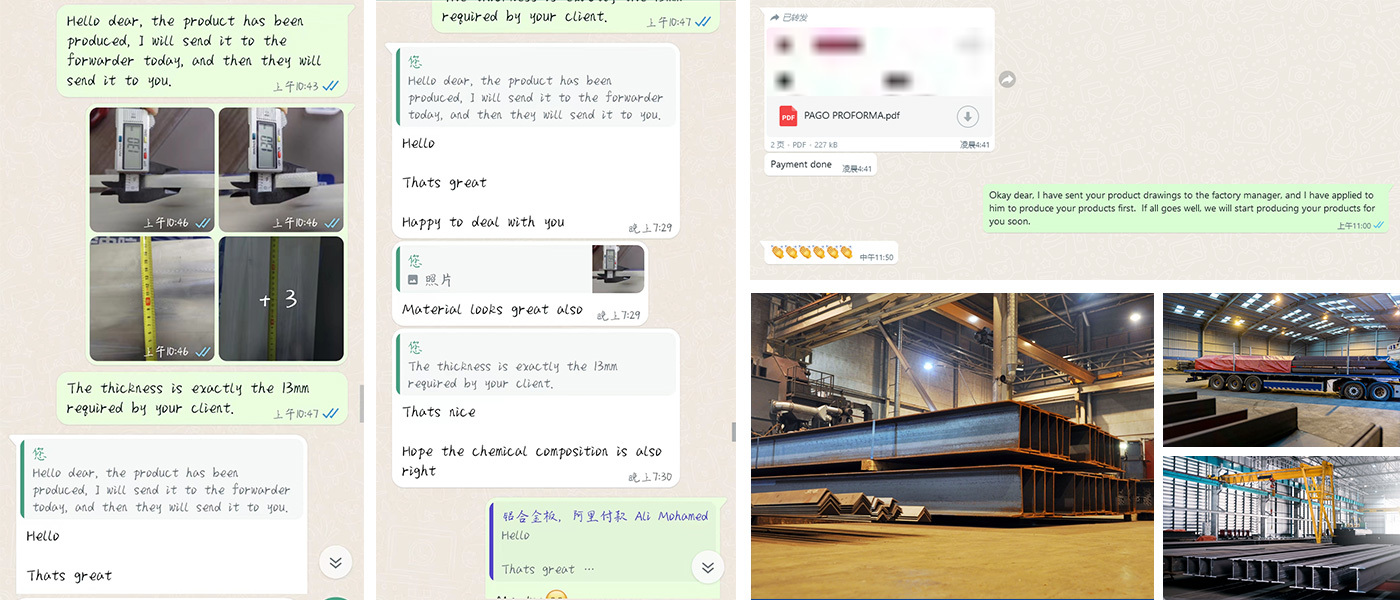

CUSTOMER TRANSACTION

STORAGE VIDEO

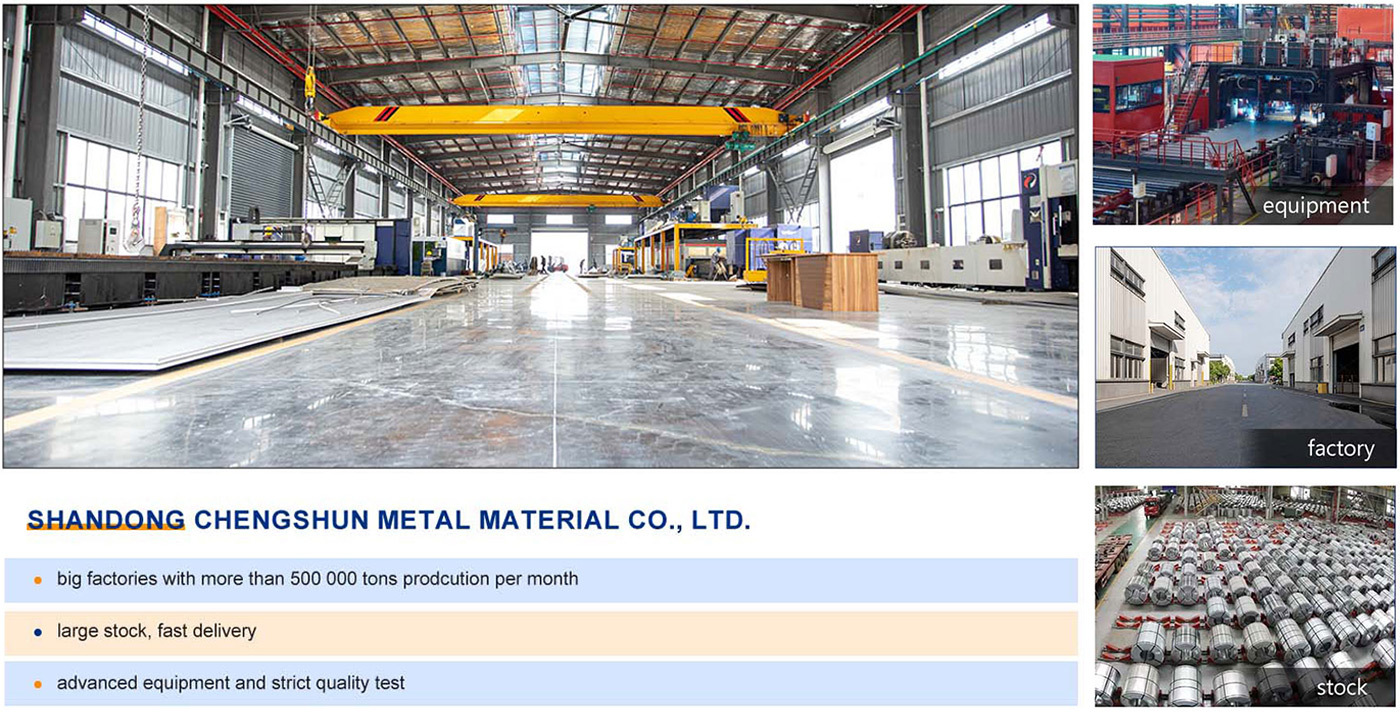

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE