Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

18CrNiMo7-6 hot rolled steel round bars

Product Details

Product introduction

18CrNiMo7-6 hot rolled steel round bars information

18CrNiMo7-6 is a case hardening steel with high toughness. There are a number of variants with high cleanliness requirements. All variants possess tighter composition ranges compared to the standard. produced with the quality class IQ (isotropic quality). This ensures a very low number of elongated sulphide inclusions which will give more isotropic properties. The high oxidic cleanliness will enable the steel to meet the same high cleanliness demands as for re-melted qualities

Product parameters

Chemical Composition

| Standard | Grade | C | Mn | P | S | Si | Ni | Cr | Mo |

EN 10084 |

18CrNiMo7-6 | 0.15-0.21 |

0.50-0.90 |

≤ 0.025 |

≤ 0.035 |

≤ 0.04 |

1.4-1.7 |

1.5-1.8 |

0.25-0.35 |

| 1.6587 |

Physical Property

| Density, g/cm3 | 7.85 | ||||

| Specific heat capacity J/(kg.K) | 460 | ||||

| Electric resistivity Ohm.mm2 /m | 0.18 | ||||

| Electric conductivity Siemens.m/mm2 | 5.55 | ||||

| Modulus of elasticity Gpa | 210 | ||||

| Thermal expansion 10^6 m/(m.K) | 100 ℃ | 200 ℃ | 300 ℃ | 400 ℃ | 500 ℃ |

| 11.1 | 12.1 | 12.9 | 13.5 | 13.9 | |

Mechanical Property

| Size mm | ≤ 11 | 12-30 | 31-63 |

| R Mpa | 1180-1420 | 1080-1320 | 980-1270 |

| Rp 0.2 Mpa | ≥ 835 | ≥785 | ≥ 685 |

| A % | ≥ 7 | ≥ 8 | ≥ 5 |

| C % | ≥ 30 | ≥ 35 | ≥ 35 |

| Kv J | ≥ 44 | ≥ 44 | |

| Hardness HB | 354-406 | 327-384 | 295-373 |

Forging

DIN 1.6587 | 17CrNiMo6 |18CrNiMo7-6 forging temperature:900 – 1100°C,cool slowly in the sand after forged.

Heat Treatment

- Normalizing:850 – 880°C/air

- Soft annealing:650 – 700°C/furnace

- Stress relieve:630- 650oC

- Carburising:880 – 980°C

- Core hardening:830 – 870°C/water

- Intermediate annealing:630 – 650°C

- Case hardening:780 – 820°C/water

- Tempering:150 – 200°C

Surface Hardness

- Treated to improveshearability(+S):Max 255HB

- Soft annealed(+A):Max 229HB

- Treated to hardness range(+TH):179-229HB

- Treated to ferrite-pearlite structure and hardness range(+FP):159-207HB

Application

DIN 1.6587 | 17CrNiMo6 |18CrNiMo7-6 steel for the parts which require core tensile strength and high hardness. Susceptible to the large seized parts with high wearing resistance and loading such as: Heavy Duty Bushings and Bearings, Cam Followers, Clutch Dogs, Compressor Bolts, Extractors, Fan Shafts, Heavy Duty Gears, Pump Shafts, Sprockets, Tappets, Wear Pins, Wire Guides etc..

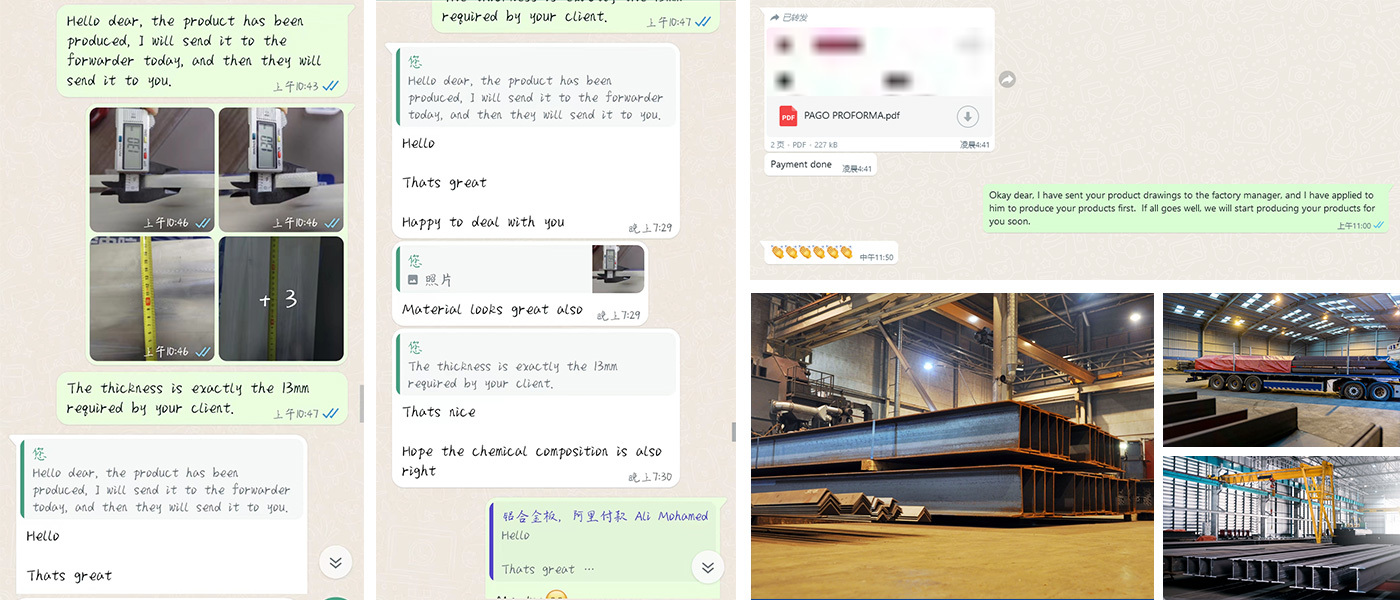

CUSTOMER TRANSACTION

STORAGE VIDEO

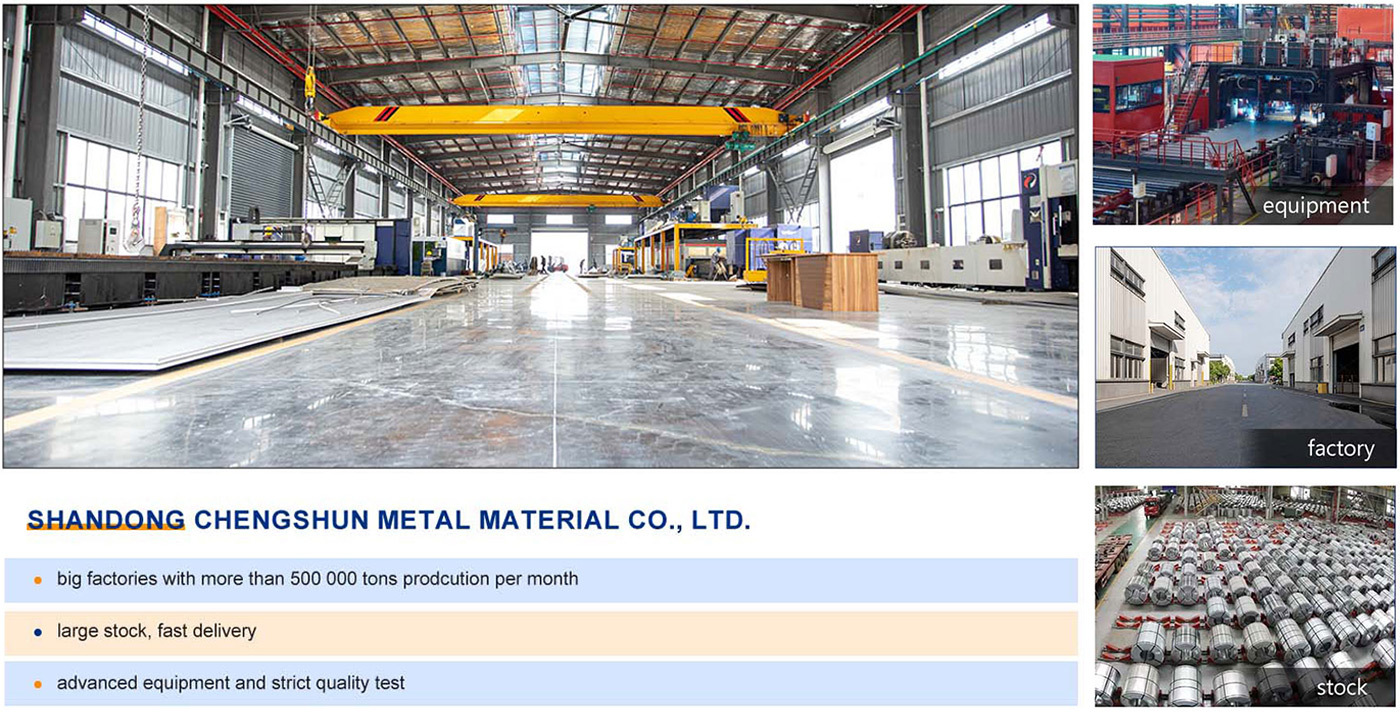

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE