Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

38CrMoAl hot rolled steel round bars

Product Details

Product introduction

38CrMoAl hot rolled steel round bars information

A Small Story of 38CrMoAl Special Alloy Steel Round Bar. 38CrMoAl is a nitrided Alloy Steel with high wear resistance, high fatigue strength and high strength. It is mainly used for nitrided parts with precise dimensions after heat treatment, or various nitrided parts with low impact load and high wear resistance

It is mainly used for nitrided parts with precise dimensions after heat treatment, or various nitrided parts with low impact load and high wear resistance. Such as boring bar, grinding machine spindle, automatic lathe spindle, worm, precision screw, precision gear. And also such as High-pressure valves, valve stems, gauges, templates, rollers, replicas, cylinder blocks, compressor piston rods, governors on steam turbines, rotating sleeves, fixing sleeves, various wear-resistant parts on rubber and plastic extruders, etc.

Chemical and Mechanical

38CrMoAl steel chemical composition:

| Materail | Chemical Composition % | ||||||

| C | Si | Mn | S/P | AL | Cr | Mo | |

| 38CrMoAl | 0.35-0.42 | 0.20-0.45 | 0.30-0.60 | 0.030 max | 0.70-1.10 | 0.80-1.10 | 0.15-0.25 |

38CrMoAl steel mechanical properties:

| Mechanical Properties | ||||

| Yield Strength (MPa) | Tensile Strength (MPa) | Elongation | Reduction of area | |

| 980 min | 830 min | 12% min | 50% min | |

The order delivery condition as follow :

–1.Hot Rolled;;Black Surface

–2.Hardness:160~260HB

–3.Length:4000~6000mm

–4.UT-SEP 1921C/C or Better

–5.Chmical Analyzed 38CrMoAl ( or 1.8509 )

–6.Fix Diameter ( Accept the tolerance -/+1.5mm)

–7.SGS or other third party inspection under buyer‘s arrangement

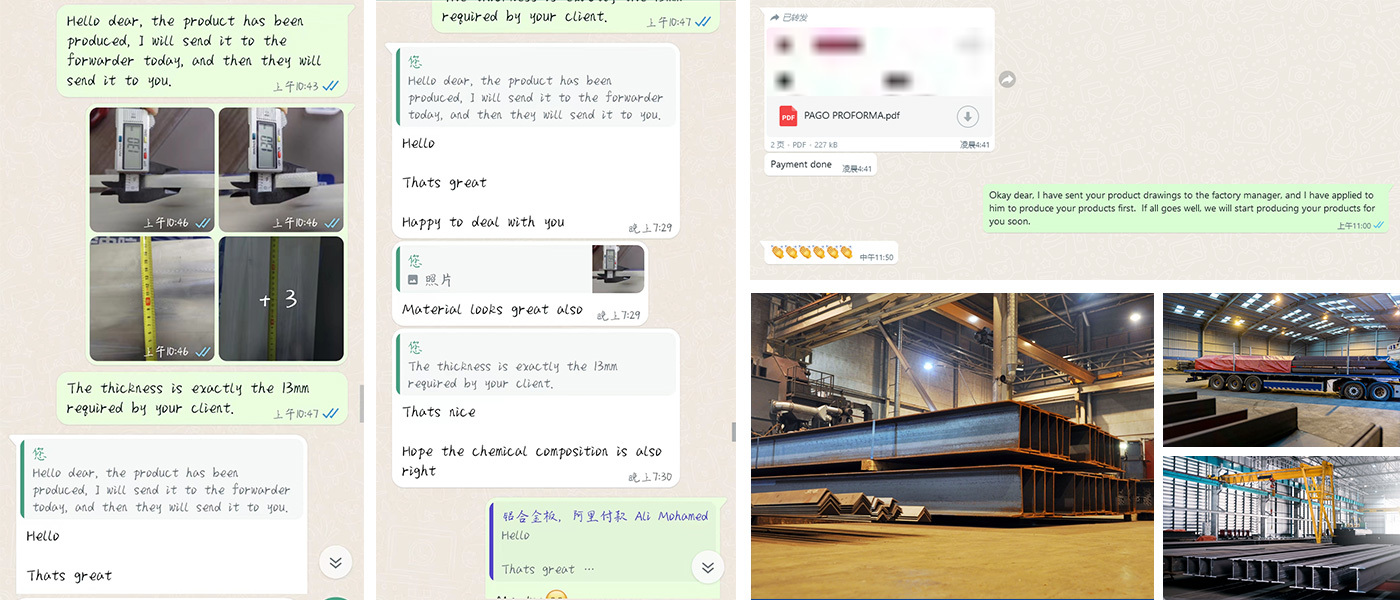

As we prepared the goods ,and informed customer to arrange third party inspeaction .

Order inspector of 38CrMoAl Alloy Steel Round bar .

The customer arrange AGS test for the goods . (test the Diameter / Length / Qty (PC) and weight before loading by container )

And there is feedback of the test is ” Uncceptable “for the goods .

Test feedback as follow :

1.The inspection result was failed due to there was rusty mark on almost all the products

2.There was no scale provided for unit weight check;

3.The actual material on labels was “38CrMoALA” not conformed to the client spec “38CrMoAl”

4.For the diameter check, for item 3-75×6000-7500mm, the actual diameter was 73mm. For item 4-80×6000-7500mm, the actual diameter was 78mm .For item 5-85×6000-7500mm, the actual diameter was 83mm.

For hardness check, material strength test, stainless steel material check, chemical composition analysis, there was no equipment or testing report provided on site.so customer accept our QC’s material test report .

After our QC feedback for the test process of inspector,the inspector did not do the steel test before ,and there without some mistake of the test way .

CUSTOMER TRANSACTION

STORAGE VIDEO

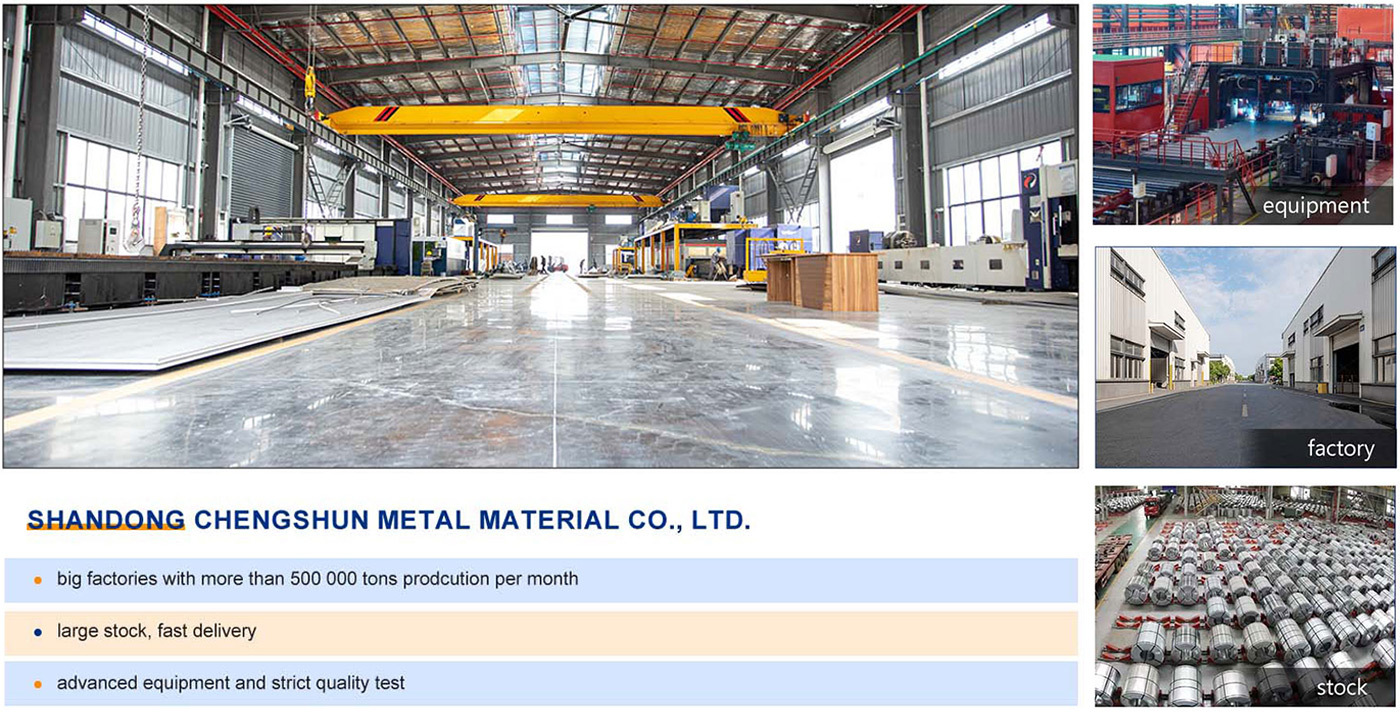

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE