Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

16MnCr5 hot rolled steel round bars

Product Details

16MnCr5 hot rolled steel round bars information

16MnCr5 steel are alloyed case hardening engineering steels for parts which require core tensile strength of 800 – 1100 N/mm² and good wearing resistance. It is an engineering material typically used to manufacture piston bolts, camshafts, levers and other vehicle and mechanical engineering components.

EN 1.7131 steel (16MnCr5 material) is an European standard carburized steel (case hardening steel) with good hardenability and machinability. For larger cross-section parts, high surface hardness and wear resistance can be obtained after heat treatment, and low-temperature impact toughness is also high. For specification and datasheet, please see the tables below.

16MnCr5 steel is generally used after carburizing and quenching, and is mainly used for manufacturing gears, worms, sealing bushings and other components.

Chemical composition

The following table shows chemical composition of 16MnCr5 material (1.7131 steel).

| Chemical Composition % | |||||||

| Standard | Steel Name (Steel Number) | C | Si ≤ | Mn | P ≤ | S | Cr |

| EN 10084 | 16MnCr5 (1.7131) | 0.14-0.19 | 0.40 | 1.00-1.30 | 0.025 | ≤ 0.035 | 0.80-1.10 |

Mechanical Properties of 1.7131 Steel (16MnCr5 Material)

1.7131 material, 16MnCr5 steel Brinell hardness

- Soft annealed: ≤ 207 HBW

- Treated to hardness: 156-207 HBW

- Treated to ferrite-pearlite structure and hardness: 140-187 HBW

- Normalized: 138-187 HBW

EN 1.7131, 16MnCr5 Tensile strength (after hardening and tempering at 200 °C)

- Dia. ≤ 16mm: Min. 1000 MPa

- 16 < Dia. ≤ 40mm: Min. 800 Mpa

- 40 < Dia. ≤ 100mm: Min. 600 Mpa

Heat Treatment Specification of 16MnCr5 (1.7131 Steel)

- End quench test Austenitizing temperature: 870℃ (30-35 minutes)

- Carburizing temperature: 880-980 ℃

- Core-hardening temperature: 860-900 ℃

- Case-hardening temperature: 780-820 ℃

- Tempering: 150 – 200 ℃ (≥ 1 hour)

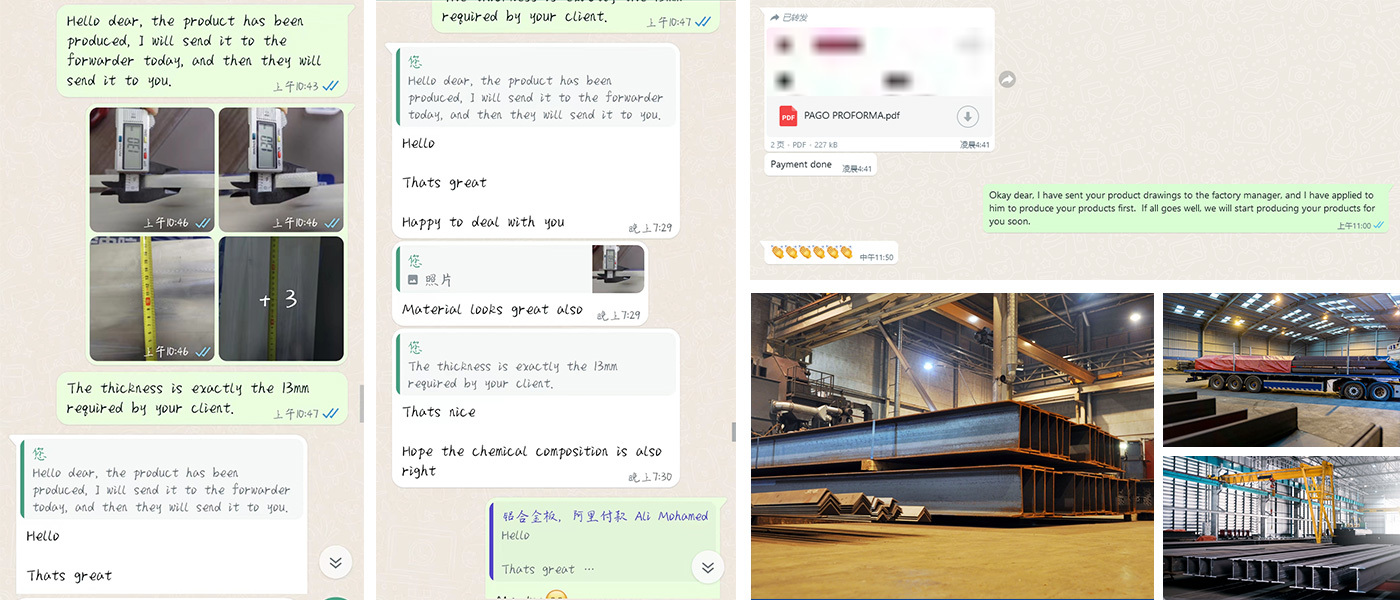

CUSTOMER TRANSACTION

STORAGE VIDEO

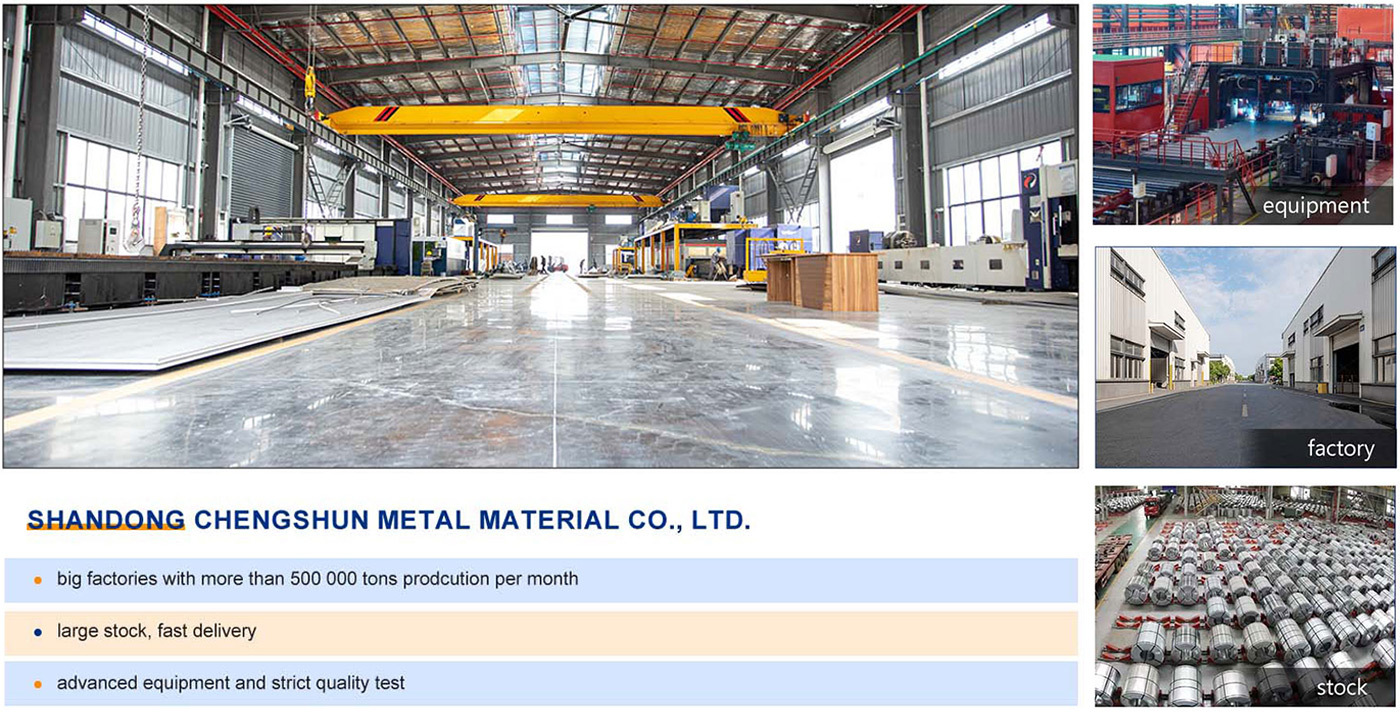

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE