Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

UNS S31703 stainless

Product Details

Product information

317L is molybdenum-bearing austenitic stainless steel with greatly increased resistance to chemical attack as compared to the conventional chromium-nickel austenitic stainless steels such as Type 304. 317L alloy also offers higher creep, stress-to-rupture, and tensile strength at elevated temperatures than conventional stainless steels. The alloy has low carbon to provide resistance to sensitization during welding and other thermal processes. This alloy is intended for severe service conditions such as flue gas desulfurization (FGD) systems.

Technical data

Chemical Composition - Stainless Steel 317/317L

| Grade | 317 | 317L |

|---|---|---|

| UNS Designation | S31700 | S31703 |

| Carbon (C) Max. | 0.08 | 0.035* |

| Manganese (Mn) Max. | 2.00 | 2.00 |

| Phosphorous (P) Max. | 0.040 | 0.04 |

| Sulphur (S) Max. | 0.03 | 0.03 |

| Silicon (Si) Max. | 1.00 | 1.00 |

| Chromium (Cr) | 18.0–20.0 | 18.0–20.0 |

| Nickel (Ni) | 11.0–14.0 | 11.0–15.0 |

| Molybdenum (Mo) | 3.0–4.0 | 3.0–4.0 |

| Nitrogen (N) | — | — |

| Iron (Fe) | Bal. | Bal. |

| Other Elements | — | — |

Typical Mechanical Properties- Stainless Steel 317L

| Material | Ultimate Tensile Strength (Mpa) | 0.2 % Yield Strength (Mpa) | % Elongation in 2" | Rockwell B Hardness |

| Alloy 317 | 515 | 205 | 35 | 95 |

| Alloy 317L | 515 | 205 | 40 | 95 |

| Minimum Mechanical Properties by ASTM A240 and ASME SA 240 | ||||

| Physical Properties | Metric | English | Comments |

| Density | 8 g/cc | 0.289 lb/in³ | |

| Mechanical Properties | |||

| Hardness, Brinell | Max 217 | Max 217 | ASTM A240 |

| Tensile Strength, Ultimate | Min 515 MPa | Min 74700 psi | ASTM A240 |

| Tensile Strength, Yield | Min 205 MPa | Min 29700 psi | ASTM A240 |

| Elongation at Break | Min 40 % | Min 40 % | ASTM A240 |

| Modulus of Elasticity | 200 GPa | 29000 ksi | |

| Electrical Properties | |||

| Electrical Resistivity | 7.9e-005 ohm-cm | 7.9e-005 ohm-cm | |

| Magnetic Permeability | 1.0028 | 1.0028 | fully annealed 0.5″ plate; 1.0028 65% cold-worked 0.5″ plate |

317L(1.4438) General Property

Alloy 317LMN and 317L are molybdenum-bearing austenitic stainless steel tube with greatly increased resistance to chemical attack as compared to the conventional chromium-nickel austenitic stainless steel pipe such as Alloy 304. In addition, 317LMN and 317L alloys offer higher creep, stress-to-rupture, and tensile strengths at elevated temperatures than conventional stainless steels. All are low carbon or "L" grades to provide resistance to sensitization during welding and other thermal processes.

The "M" and "N" designations indicate that the compositions contain increased levels of molybdenum and nitrogen respectively. The combination of molybdenum and nitrogen is particularly effective in enhancing resistance to pitting and crevice corrosion, especially in process streams containing acids, chlorides, and sulfur compounds at elevated temperatures. Nitrogen also serves to increase the strength of these alloys. Both alloys are intended for severe service conditions such as flue gas desulfurization (FGD) systems.

In addition to excellent corrosion resistance and strength properties, the Alloys 316, 316L, and 317L Cr-Ni-Mo alloys also provide the excellent fabricability and formability which are typical of the austenitic stainless steel tubing .

317L (1.4438) Heat Treatment

Annealing

The austenitic stainless steel pipe are provided in the mill annealed condition ready for use. Heat treatment may be necessary during or after fabrication to remove the effects of cold forming or to dissolve precipitated chromium carbides resulting from thermal exposures. For the Alloys 316 and 317L the solution anneal is accomplished by heating in the 1900 to 2150°F (1040 to 1175°C) temperature range followed by air cooling or a water quench, depending on section thickness. Cooling should be sufficiently rapid through the 1500 to 800°F (816 to 427°C) range to avoid reprecipitation of chromium carbides and provide optimum corrosion resistance. In every case, the metal should be cooled from the annealing temperature to black heat in less than three minutes.

Forging

The recommended initial temperature range is 2100-2200°F (1150-1205°C) with a finishing range of 1700-1750°F (927-955°C).

Annealing

317LMN and Alloy 317L stainless steels can be annealed in the temperature range 1975-2150°F (1080-1175°C) followed by an air cool or water quench, depending on thickness. Plates should be annealed between 2100°F (1150°C) and 2150°F (1175°C). The metal should be cooled from the annealing temperature (from red/white to black) in less than three minutes.

Hardenability

- These grades are not hardenable by heat treatment.

- Alloys 316 and 317L stainless steel tube cannot be hardened by heat treatment.

FAQ

Q:Will you delivery the goods on time?

A:Yes,we promise to provide best quality products and delivery on time.Honesty is our company's tenet.

Q:Do you provide samples?is it free or extra?

A:The sample could can provide for customer with free,but the courier freight will be covered by customer account.

Q:Do you accept the third party inspection?

A:Yes absolutely we accept.

Q:What are your main products?

A:Carbon steel,alloy steel,stainless steel plate/coil,pipe and fittings,sections etc.

Q:Can you accept the order of customzied?

A:Yes,we assure.

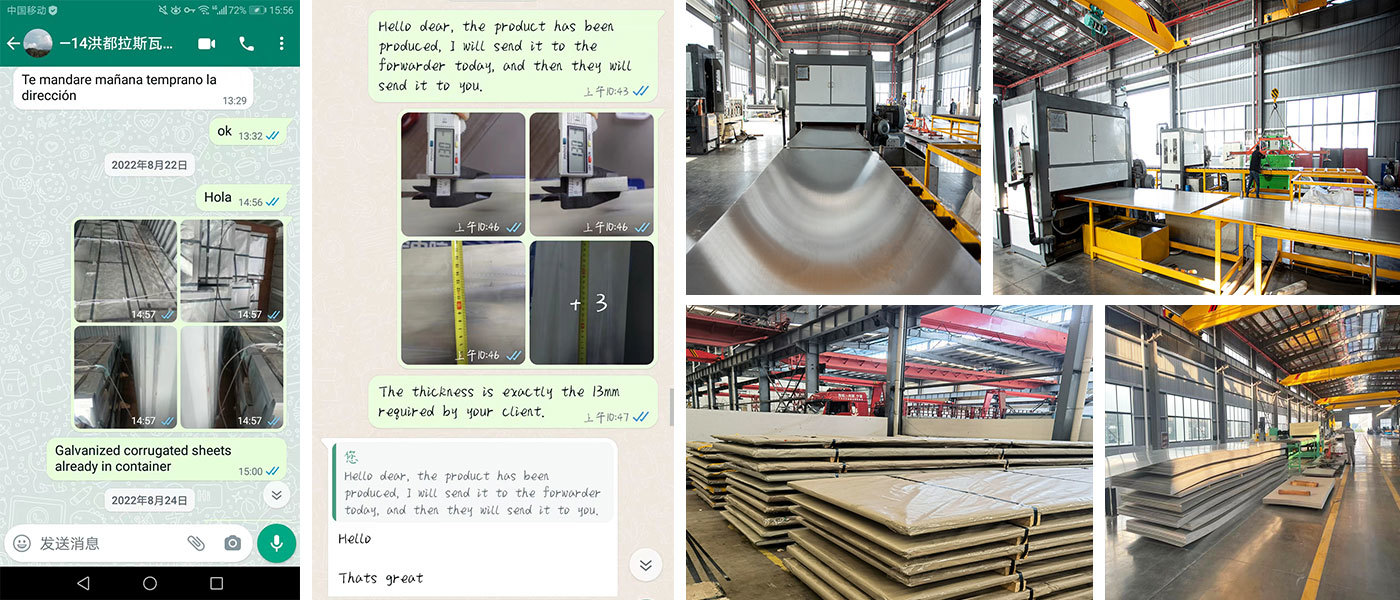

CUSTOMER TRANSACTION

Always adhere to the tenet of high quality, low cost, fast pace and excellent service. Shandong Chengshun Metal Materials Co., Ltd. is willing to cooperate sincerely with friends from all walks of life at home and abroad for common development.

STORAGE VIDEO

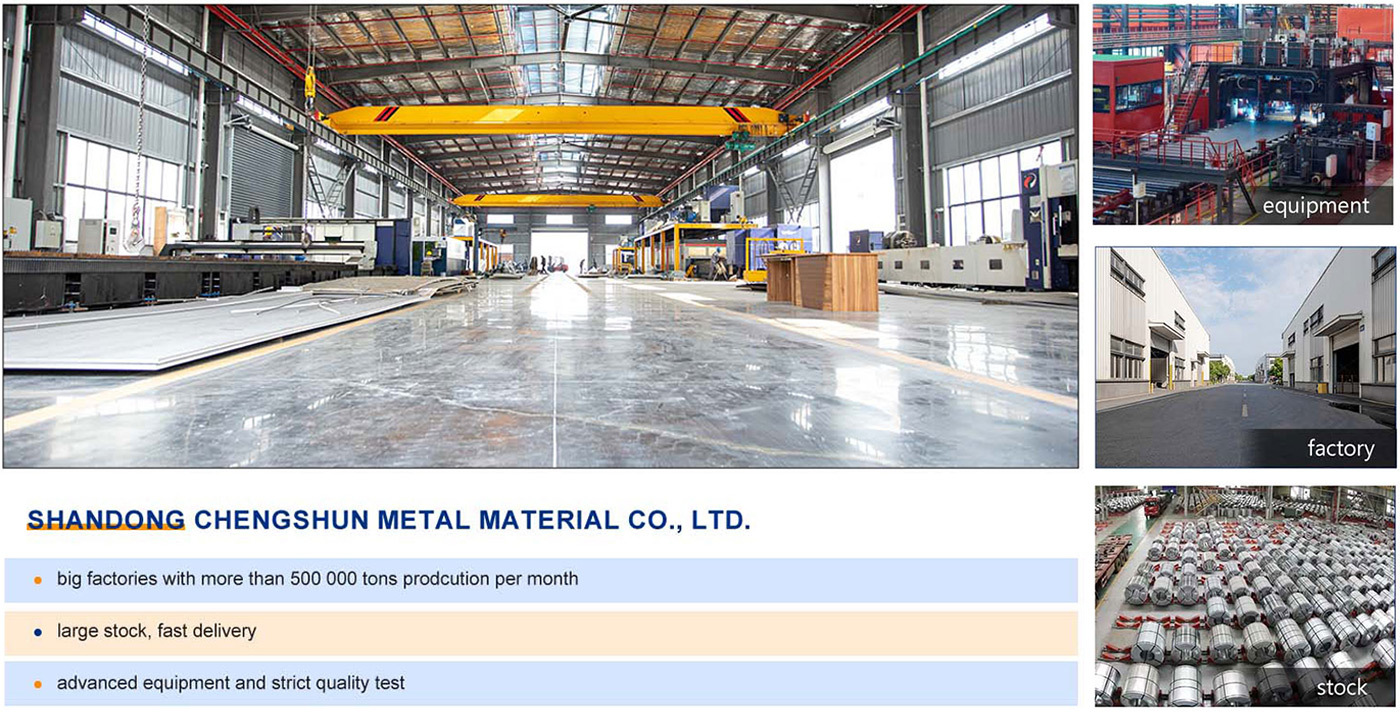

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

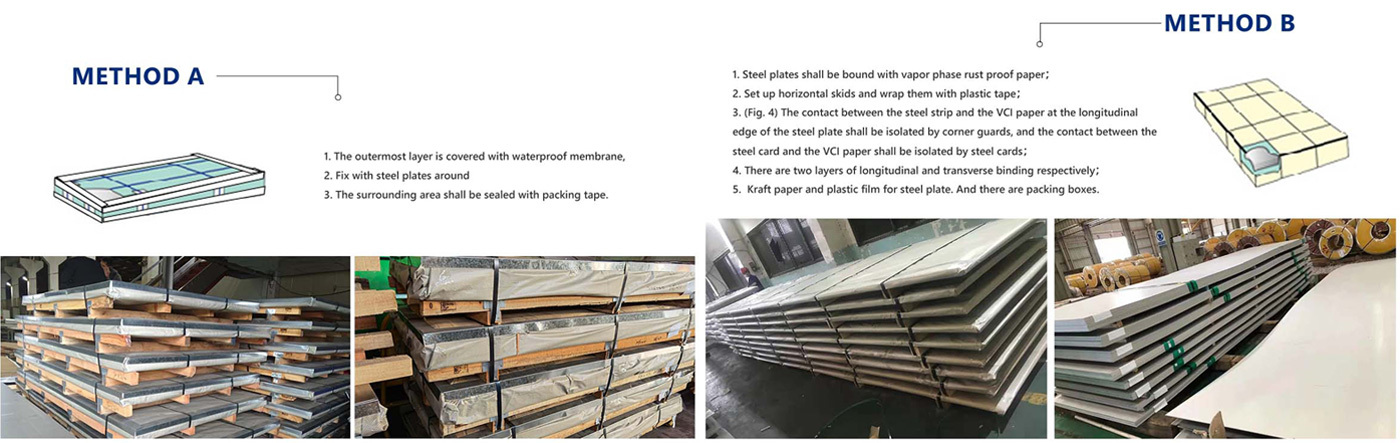

Packing and shipping

Mainly exported to Europe, Southeast Asia, South Africa, the Middle East, Latin America and other countries and regions, the products are favored by Chinese and foreign users.

product display

Application field

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE