Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

34CrNiMo6 hot rolled steel round bars

Product Details

1. 34CrNiMo6 hot rolled steel round bars Application

EN DIN 34CrNiMo6 steel is used to make tools which demands good plasticity and high strength. It is usually selected to make the big size and important parts, such as heavy machinery axle,turbine shaft blade, high load of transmission parts, fasteners, crank shafts, gears, as well as heavily loaded parts for motor construction etc.

is reliable to supply engineering 34CrNiMo6 steels / 1.6582 engineering alloy steels. Please tell us your detailed requirements and have the best offer soon.

2. Chemical and Mechanical

34CrNiMo6 Chemical composition and Equivalents steel grade properties

| BS EN 10083 – 3:2006 | 34CrNiMo6 | C | Si | Si | P | S | Cr | Mo | Ni |

| 0.30-0.38 | 0.40 Max | 0.50-0.80 | 0.025 max | 0.035 max | 1.30-1.70 | 0.15-0.30 | 1.30-1.70 |

34CrNiMo6 Steel Mechanical Properties

| Diameter(mm) | < 16 | 16~ 40 | 40~100 | 100~160 | 160 ~250 |

| Thickness t (mm) | < 8 | 8~20 | 20~60 | 60~100 | 100~160 |

| Tensile strength Rm (N/mm2) | 1200 – 1400 | 1100 – 1300 | 1000 – 1200 | 900 – 1100 | 800 – 950 |

| Elongation A (%) | 9 min | 10 Min | 11 Min | Min 12 | 13 Min |

| Reduction of area Z (%) | 40Min | 45 Min | 50Min | 55Min | 55MIn |

| Toughness CVN (J) | 35Min | 45Min | 45Min | 45Min | 45 Min |

| Yield strength Re (N/mm²) | 1000 Min | 900 Min | 800 Min | 700 Min | 600 Min |

EN 34CrNiMo6 Steel Standards And Equivalents

| BS EN 10083 -3: 2006 | 34CrNiMo6 / 1.6582 | ASTM A29: 2004 | 4337 |

| BS EN 10250 – 3: 2000 |

3. EN/DIN 34CrNiMo6 Steel Chemical Composition Properties

| BS EN 10083 – 3:2006 | 34CrNiMo6 /1.6582 |

C | Mn | Si | P | S | Cr | Mo | Ni |

| 0.30-0.38 | 0.5-0.8 | 0.40 max | 0.025 max | 0.035 max | 1.3-1.7 | 0.15-0.30 | 1.3-1.7 | ||

| BS EN 10250-3:2000 | C | Mn | Si | P | S | Cr | Mo | Ni | |

| 0.30-0.38 | 0.5-0.8 | 0.40 max | 0.035 max | 0.035 max | 1.3-1.7 | 0.15-0.30 | 1.3-1.7 | ||

| ASTM A29: 2004 | 4337 | C | Mn | Si | P | S | Cr | Mo | Ni |

| 0.30-0.40 | 0.6-0.8 | 0.20-0.35 | 0.035 max | 0.040 max | 0.70-0.90 | 0.20-0.30 | 1.65-2.00 |

4.Mechanical Properties of EN/DIN 34CrNiM06 / 1.6582 Alloy Steel

| Properties | < 16 | >16 – 40 | >40 – 100 | >100 – 160 | >160 – 250 |

| Thickness t [mm] | < 8 | 8<t<20 | 20<t<60 | 60<t<100 | 100<t<160 |

| Yield strength Re [N/mm²] | min. 1000 | min. 900 | min. 800 | min. 700 | min. 600 |

| Tensile strength Rm [N/mm2] | 1200 – 1400 | 1100 – 1300 | 1000 – 1200 | 900 – 1100 | 800 – 950 |

| Elongation A [%] | min. 9 | min. 10 | min. 11 | min. 12 | min. 13 |

| Reduction of area Z [%] | min. 40 | min. 45 | min. 50 | min. 55 | min. 55 |

| Toughness CVN [J] | min. 35 | min. 45 | min. 45 | min. 45 | min. 45 |

5.Heat Treatment of 34CrNiMo6 Engineering Steel

Quenched and Tempered (Q+T) of 34CrNiMo6 Steel

- Heat 34CrNiMo6 round steel slowly to the temperature of 850°C;

- Soak at this hardening temperature quench in oil;

- Temper as soon as 34CrNiMo6 steels reach room temperature.

- Heat uniformly to the suitable temperature;

- Withdraw from the furnace and cool in the air.

- The usual tempering temperature is 600°C which depending on the actual requirements.

6.Forging of DIN 34CrNiMo6 / 1.6582 Steel

Hot forming temperature: 1100-900oC.

7.Machinability of Steel 34CrNiMo6

Machining is best done with this 1.6582 alloy steel in the annealed or normalized and tempered condition. It can be machined by all conventional methods.

8.Welding

The alloy materials can be fusion or resistance welded. Preheat and post heat weld procedures should be followed when welding this alloy by established methods.

9.Application

EN DIN 34CrNiMo6 steel is used to make tools which demands good plasticity and high strength. It is usually selected to make the big size and important parts, such as heavy machinery axle,turbine shaft blade, high load of transmission parts, fasteners, crank shafts, gears, as well as heavily loaded parts for motor construction etc.

is reliable to supply engineering 34CrNiMo6 steels / 1.6582 engineering alloy steels. Please tell us your detailed requirements and have the best offer soon.

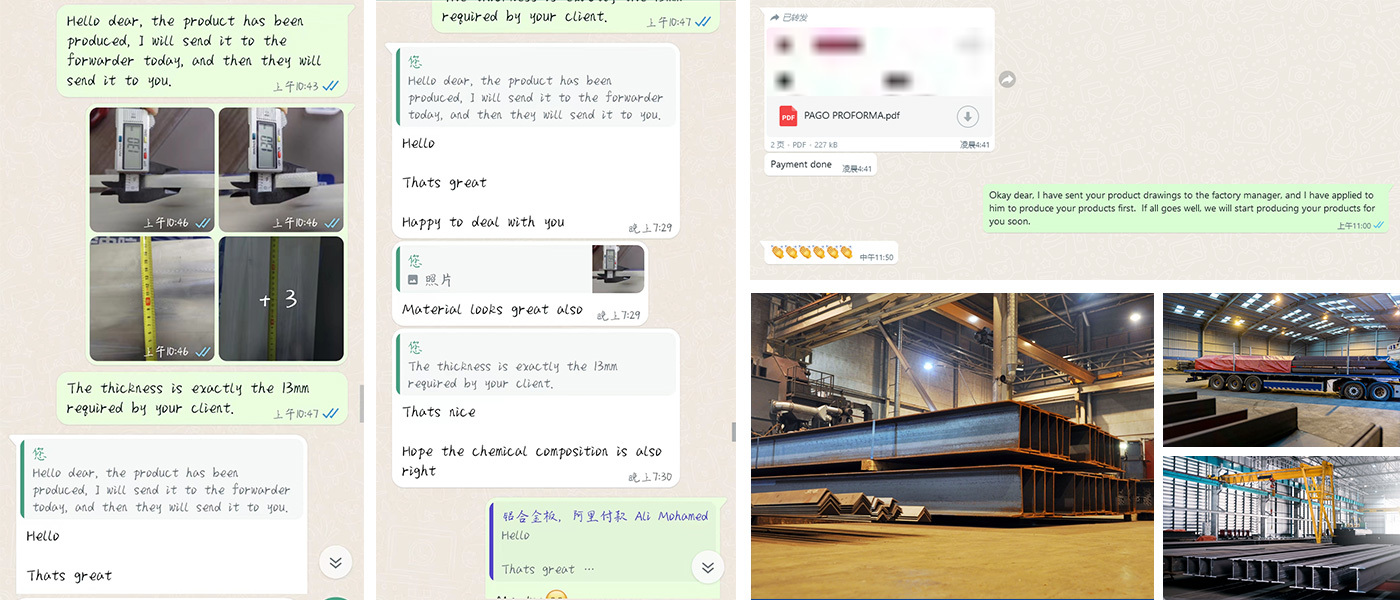

CUSTOMER TRANSACTION

STORAGE VIDEO

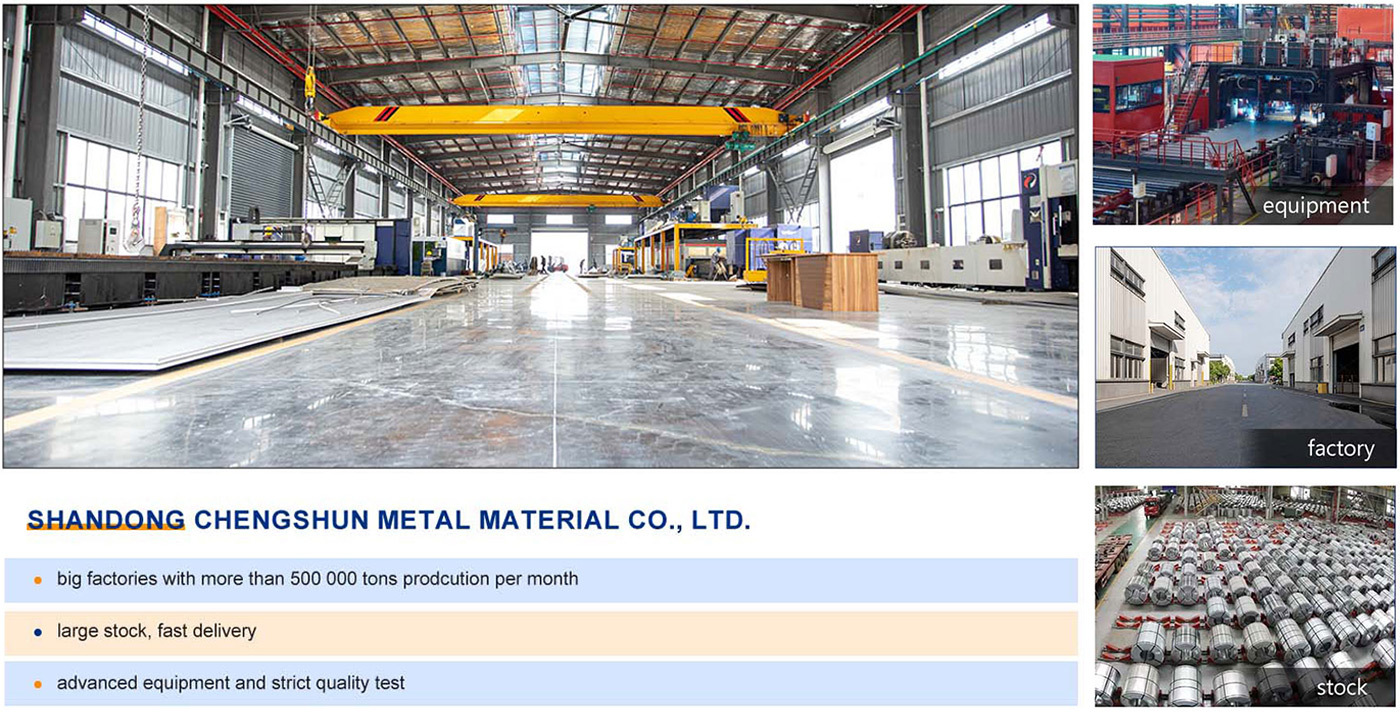

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE