Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

W6Mo5Cr4V2Co5(M35) hot rolled steel round bars

Product Details

Product introduction

W6Mo5Cr4V2Co5 is a tungsten-molybdenum series general cobalt-containing high-speed steel. Compared with W6Mo5Cr4V2, it has improved red hardness and high temperature hardness, improved wear resistance, and has better machinability, but the strength and impact toughness are lower, and it is easy to oxidize and decarburize. W6Mo5Cr4V2Co5 is general Used as gear cutters, milling tools, punches, cutter heads and other tools for cutting hard materials.

Product parameters

|

Product Name |

High Speed Tool Steel |

|

Material |

Alloy Steel |

|

Model Number |

AISI ASTM M35 /DIN 1.3243 /JIS SKH55 /W6Mo5Cr4V2Co5 |

|

Delivery condition |

Cold drawn, Quenchen and Tempered, Centerless Grinding |

|

Processing Service |

Cold drawn, Grinding, Peeling, Heat treat ment |

|

Surface treatment |

Black, Grinded, Peeled, Rough turned, Polished |

|

Diameter |

2-90 mm (tolerance ISO h8,h9) |

|

Application |

cold die,blanking die,punches and variour molding tools |

|

Delivery hardness |

annealed condition ≤269HB |

|

Packing |

Water proof packing |

|

Certification |

ISO 9001, TUV, SGS, BV,CE, ABS |

Technical data

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

W |

Co |

|

0,80 - 0,90 |

0.20 - 0,45 |

0.15 - 0,40 |

<=0,030 |

<=0,030 |

3,75 - 4,50 |

4,50 - 5,50 |

1,75 - 2,25 |

5,50 - 6,50 |

4,50 - 5,50 |

Mechanical properties

Hardness: Delivery hardness: (other processing methods) ≤285HB; (annealing) ≤269HB. Sample heat treatment system and quenching and tempering hardness: ≥64HRC

Microstructure

Heat treatment specification: quenching, preheating at 730~840℃, heating at 1190~1210℃ (salt bath furnace) or 1200~1220℃ (box furnace), oil cooling, tempering at 540~560℃ twice, 2h each time.

delivery status

Hot-rolled, forged, and cold-drawn steel rods are delivered in annealed state, and hot-rolled and forged steel rods are delivered after processing by annealing + other processing methods (skinning, light drawing, polishing or polishing, etc.).

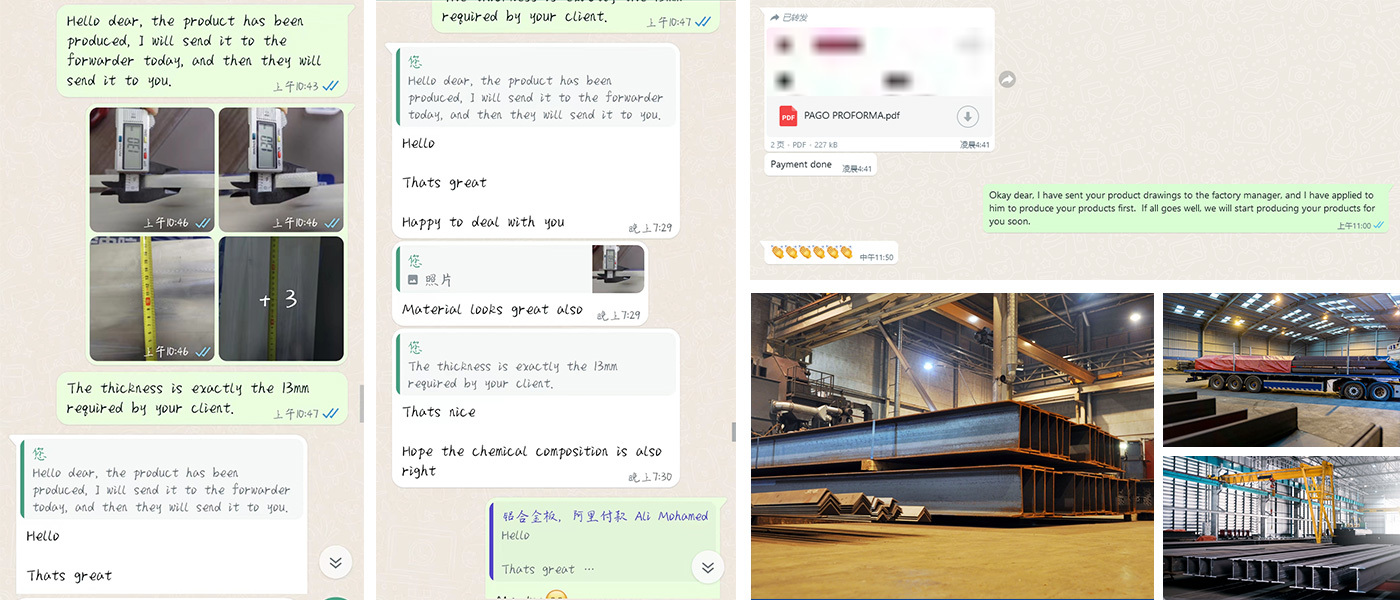

CUSTOMER TRANSACTION

STORAGE VIDEO

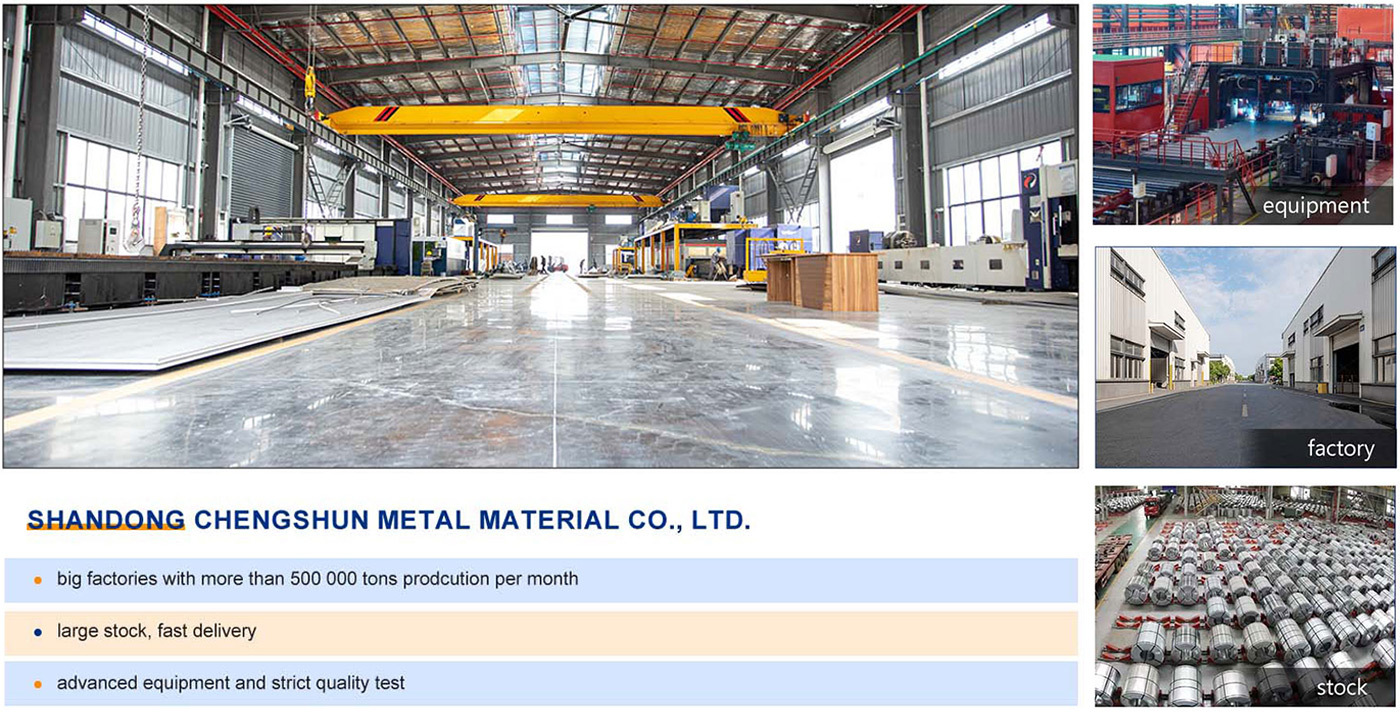

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE