Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

LSAW Steel Pipe

OD: 406mm ~ 1422 mm

WT: 6.4mm ~ 44.5mm

LENGTH: 5mtr ~ 12mtr

Standard & Grade: ASTM A53 Grade A/B/C

Product Details

Product introduction

LSAW Steel Pipe

Pipe Type: Longitudinal Welded Pipe, Longitudinal Submerged Arc Welded Pipe

Application: Used for Fluids Transmission, Structural Support in Industrial Construction

Specification: OD: 406mm ~ 1422 mm

WT: 6.4mm ~ 44.5mm

LENGTH: 5mtr ~ 12mtr

Standard & Grade: ASTM A53 Grade A/B/C

Ends: Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Surface: Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Anti-corrosive Coating

Packing: Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

SAW Steel Pipe Dimension

|

|

|||||||||||||||||

|

Out Diameter |

Wall Thickness(mm) |

||||||||||||||||

|

Inch |

mm |

6.4 |

7.1 |

7.9 |

9.53 |

12.7 |

14.3 |

15.9 |

19.1 |

22.2 |

25.4 |

28.6 |

31.8 |

34.9 |

38.1 |

41.3 |

44.5 |

|

16 |

406.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

457 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

508 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

559 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24 |

610 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

26 |

660 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

28 |

711 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

762 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

32 |

813 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

34 |

864 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

36 |

914 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

38 |

965 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40 |

1016 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

42 |

1067 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

44 |

1118 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

46 |

1168 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

48 |

1219 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

52 |

1321 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

56 |

1422 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60 |

1524 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

64 |

1626 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Technical data

olerance of Outside Diameter and Wall Thickness

|

Types |

Standard |

|||||

|

SY/T5040-2000 |

SY/T5037-2000 |

SY/T9711.1-1977 |

ASTM A252 |

AWWA C200-97 |

API 5L PSL1 |

|

|

Tube end OD deviation |

±0.5%D |

±0.5%D |

-0.79mm~+2.38mm |

<±0.1%T |

<±0.1%T |

±1.6mm |

|

Wall thickness |

±10.0%T |

D<508mm, ±12.5%T |

-8%T~+19.5%T |

<-12.5%T |

-8%T~+19.5%T |

5.0mm<T<15.0mm, ±0.11 |

|

D>508mm, ±10.0%T |

T≥15.0mm, ±1.5mm |

|||||

Chemical Composition and Mechanical Properties

|

Types |

Standard |

||||||||||

|

SY/T5040-2000 |

SY/T5037-2000 |

SY/T9711.1-1977 |

ASTM A252 |

AWWA C200-97 |

API 5L PSL1 |

||||||

|

Tube end OD deviation |

±0.5%D |

±0.5%D |

-0.79mm~+2.38mm |

<±0.1%T |

<±0.1%T |

±1.6mm |

|||||

|

Wall thickness |

±10.0%T |

D<508mm, ±12.5%T |

-8%T~+19.5%T |

<-12.5%T |

-8%T~+19.5%T |

5.0mm<T<15.0mm, ±0.11 |

|||||

|

D>508mm, ±10.0%T |

T≥15.0mm, ±1.5mm |

||||||||||

|

Standard |

Grade |

Chemical Composition(max)% |

Mechanical Properties(min) |

|

|||||||

|

C |

Mn |

Si |

S |

P |

Yield Strength(Mpa) |

Tensile Strength(Mpa) |

|

||||

|

GB/T700-2006 |

A |

0.22 |

1.4 |

0.35 |

0.050 |

0.045 |

235 |

370 |

|

||

|

B |

0.2 |

1.4 |

0.35 |

0.045 |

0.045 |

235 |

370 |

|

|||

|

C |

0.17 |

1.4 |

0.35 |

0.040 |

0.040 |

235 |

370 |

|

|||

|

D |

0.17 |

1.4 |

0.35 |

0.035 |

0.035 |

235 |

370 |

|

|||

|

GB/T1591-2009 |

A |

0.2 |

1.7 |

0.5 |

0.035 |

0.035 |

345 |

470 |

|

||

|

B |

0.2 |

1.7 |

0.5 |

0.030 |

0.030 |

345 |

470 |

|

|||

|

C |

0.2 |

1.7 |

0.5 |

0.030 |

0.030 |

345 |

470 |

|

|||

|

BS En10025 |

S235JR |

0.17 |

1.4 |

- |

0.035 |

0.035 |

235 |

360 |

|

||

|

S275JR |

0.21 |

1.5 |

- |

0.035 |

0.035 |

275 |

410 |

|

|||

|

S355JR |

0.24 |

1.6 |

- |

0.035 |

0.035 |

355 |

470 |

|

|||

|

DIN 17100 |

ST37-2 |

0.2 |

- |

- |

0.050 |

0.050 |

225 |

340 |

|

||

|

ST44-2 |

0.21 |

- |

- |

0.050 |

0.050 |

265 |

410 |

|

|||

|

ST52-3 |

0.2 |

1.6 |

0.55 |

0.040 |

0.040 |

345 |

490 |

|

|||

|

JIS G3101 |

SS400 |

- |

- |

- |

0.050 |

0.050 |

235 |

400 |

|

||

|

SS490 |

- |

- |

- |

0.050 |

0.050 |

275 |

490 |

|

|||

|

API 5L PSL1 |

A |

0.22 |

0.9 |

- |

0.03 |

0.03 |

210 |

335 |

|

||

|

B |

0.26 |

1.2 |

- |

0.03 |

0.03 |

245 |

415 |

|

|||

|

X42 |

0.26 |

1.3 |

- |

0.03 |

0.03 |

290 |

415 |

|

|||

|

X46 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

320 |

435 |

|

|||

|

X52 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

360 |

460 |

|

|||

|

X56 |

0.26 |

1.1 |

- |

0.03 |

0.03 |

390 |

490 |

|

|||

|

X60 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

415 |

520 |

|

|||

|

X65 |

0.26 |

1.45 |

- |

0.03 |

0.03 |

450 |

535 |

|

|||

|

X70 |

0.26 |

1.65 |

- |

0.03 |

0.03 |

585 |

570 |

|

|||

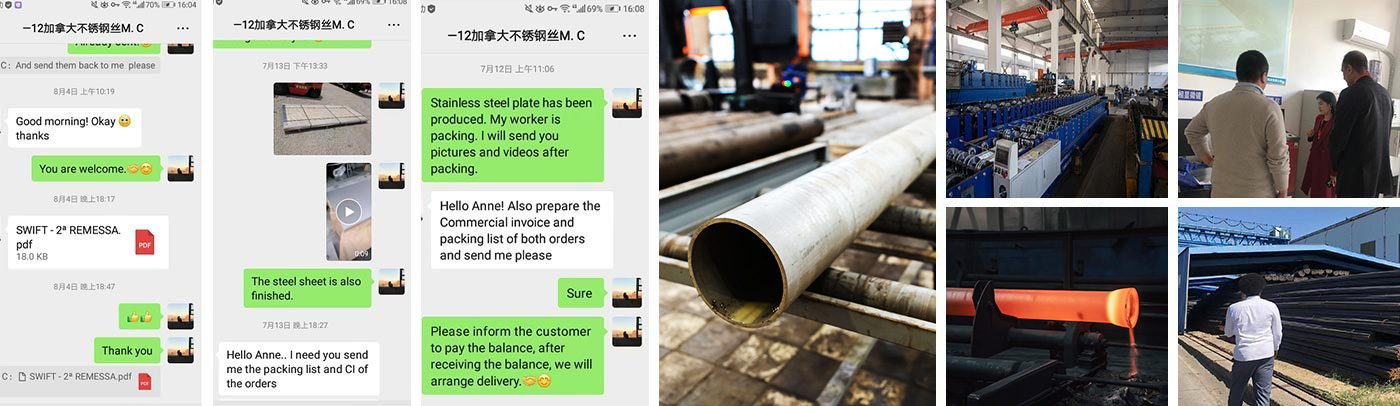

CUSTOMER TRANSACTION

Always adhere to the tenet of high quality, low cost, fast pace and excellent service. Shandong Chengshun Metal Materials Co., Ltd. is willing to cooperate sincerely with friends from all walks of life at home and abroad for common development.

STORAGE VIDEO

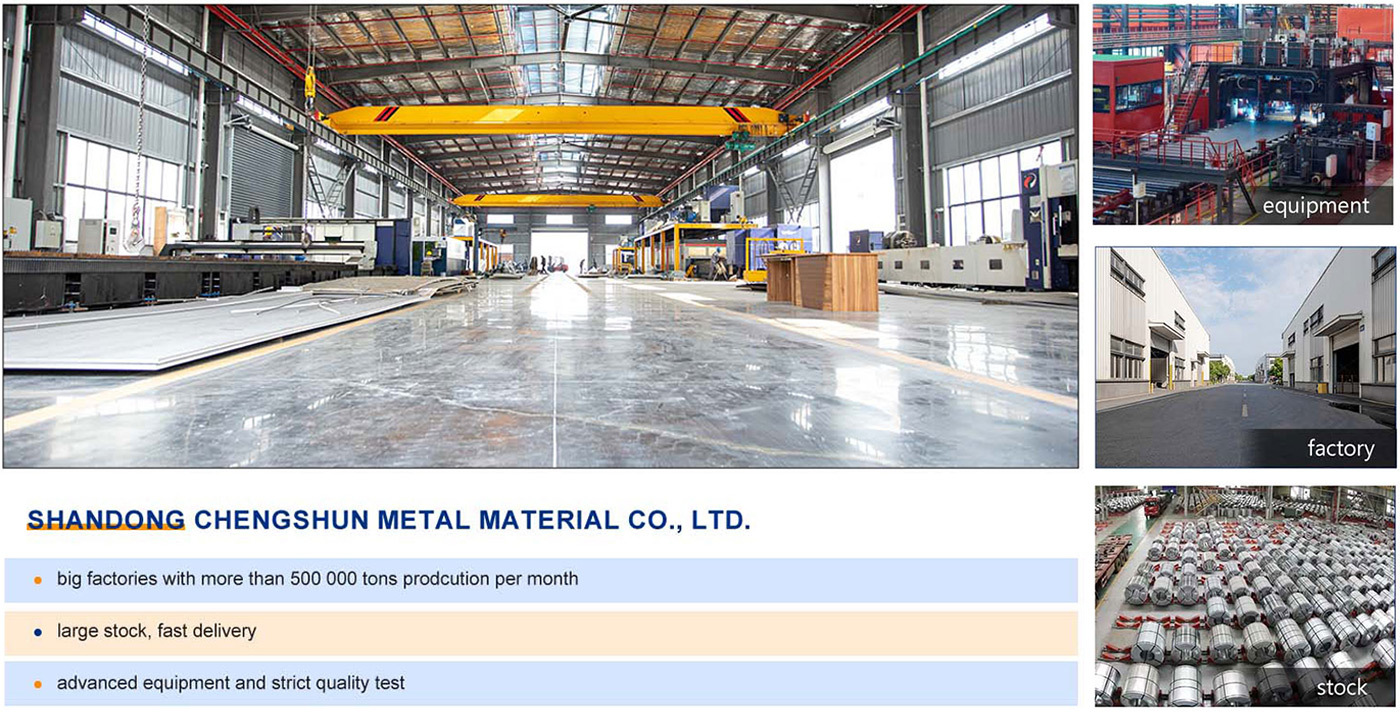

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE