Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

ASTM A514 Grade T steel plate

Product Details

Product introduction

ASTM A514 is most commonly used as structural steel in cranes and large heavy-load machines.

A514 is a particular type of high strength steel, which is quenched and tempered alloy steel, with a yield strength of 100,000 psi (100 ksi or approximately 700 MPa). The ArcelorMittal trademarked name is T-1. A514 is primarily used as a structural steel for building construction. A517 is a closely related alloy that is used for the production of high-strength pressure vessels.

This is a standard set by the standards organization ASTM International, a voluntary standards development organizations that sets technical standards for materials, products, systems, and services.

A514

The tensile yield strength of A514 alloys is specified as at least 100 ksi (689 MPa) for thicknesses up to 2.5 inches (63.5 mm) thick plate, and at least 110 ksi (758 MPa) ultimate tensile strength, with a specified ultimate range of 110–130 ksi (758–896 MPa). Plates from 2.5 to 6.0 inches (63.5 to 152.4 mm) thick have specified strength of 90 ksi (621 MPa) (yield) and 100–130 ksi (689–896 MPa) (ultimate).

A517

A517 steel has equal tensile yield strength, but slightly higher specified ultimate strength of 115–135 ksi (793–931 MPa) for thicknesses up to 2.5 inches (63.5 mm) and 105–135 ksi (724–931 MPa) for thicknesses 2.5 to 6.0 inches (63.5 to 152.4 mm).

Usage

A514 steels are used where a weldable, machinable, very high strength steel is required to save weight or meet ultimate strength requirements. It is normally used as a structural steel in building construction, cranes, or other large machines supporting high loads.

In addition, A514 steels are specified by military standards (ETL 18-11) for use as small-arms firing range baffles and deflector plates.

Chemical composition & Mechanical property

Mechnical property for A514GrT alloy steel:

| Thickness (mm) | Yield strength (≥Mpa) | Tensile strength (Mpa) | Elongation in ≥,% |

| 50mm | |||

| T≤65 | 690 | 760-895 | 18 |

| 65<T | 620 | 690-895 | 16 |

Chemical composition for A514GrT alloy steel (Heat Analysis Max%)

| Main chemical elements composition of A514GrT | |||||||

| C | Si | Mn | P | S | B | Mo | V |

| 0.08-0.14 | 0.40-0.60 | 1.20-1.50 | 0.035 | 0.020 | 0.001-0.005 | 0.45-0.60 | 0.03-0.08 |

Technical Requirements & Additional Services:

- High tension test

- Low temperature impacting test

- Simulated post-welded heat treatment (PWHT)

- Issued Orginal Mill test certificate under EN 10204 FORMAT 3.1/3.2

- When cooper steel is specified for A709 Gr36, the content Cu≥0.20%

- Shot blasting and Painting,Cutting and welding as per end user’s demands

- Heavy thicknesses (3-inches or thicker) available at most Leeco Steel distribution centers.

- Available in standard grades: 36, 50 and 50W.

- Available in high-performance grades: HPS 50W and HPS 70W.

- Customers can specify A709 grades to meet Charpy test requirement for specific zones and climate.

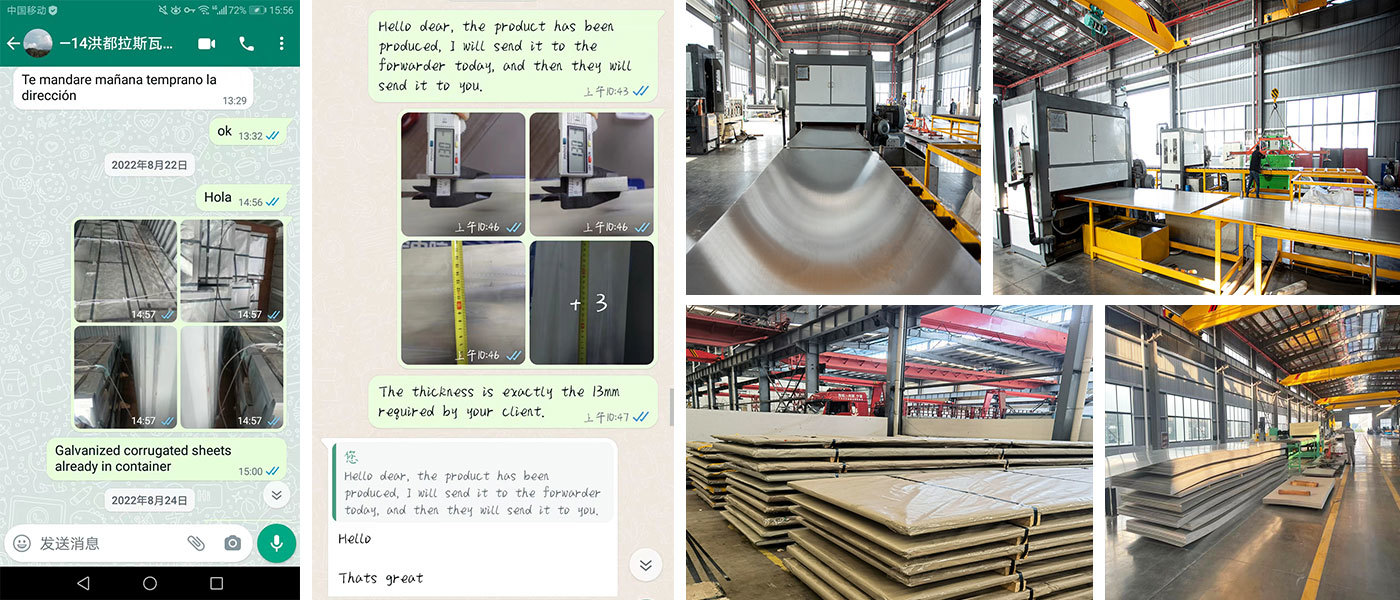

CUSTOMER TRANSACTION

Always adhere to the tenet of high quality, low cost, fast pace and excellent service. Shandong Chengshun Metal Materials Co., Ltd. is willing to cooperate sincerely with friends from all walks of life at home and abroad for common development.

STORAGE VIDEO

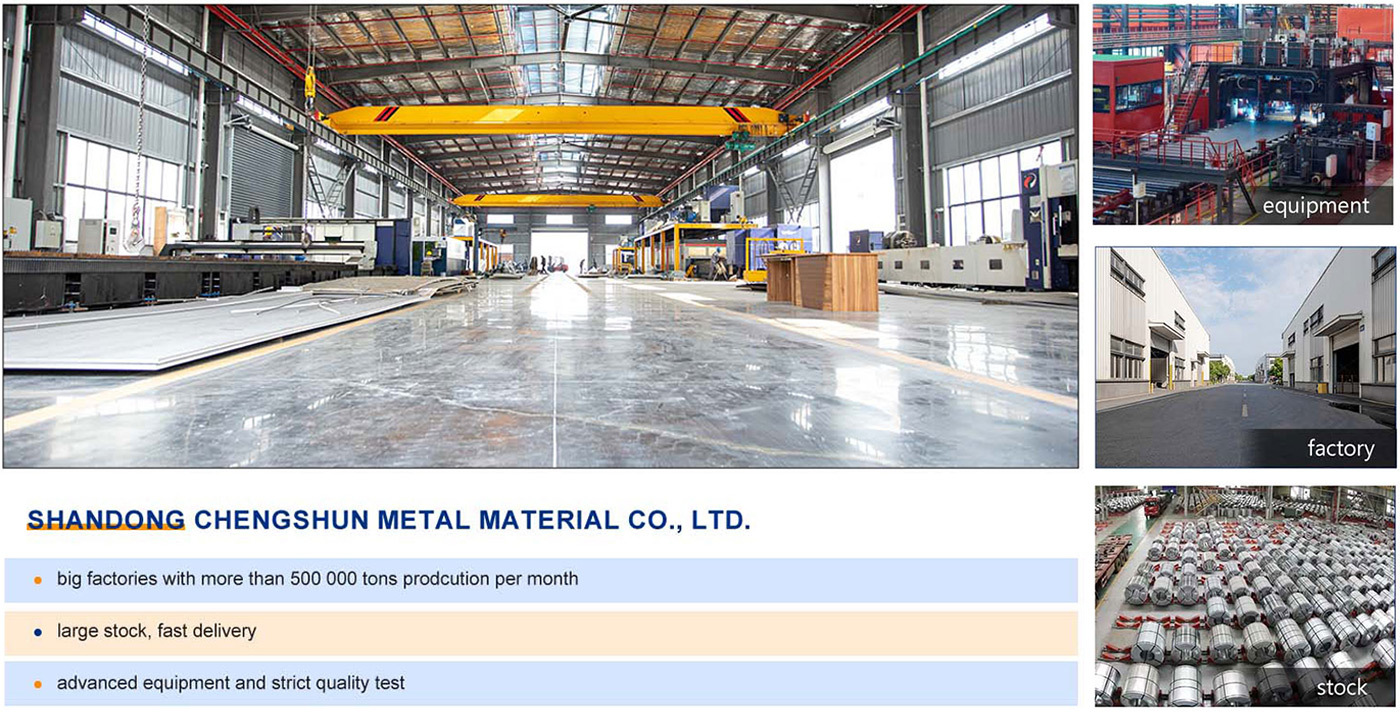

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

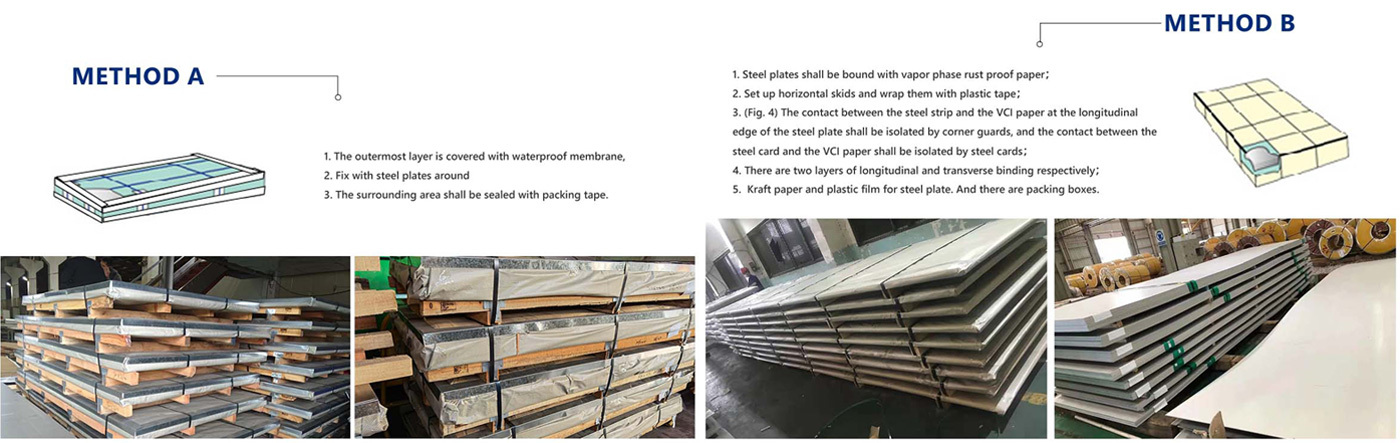

Packing and shipping

Mainly exported to Europe, Southeast Asia, South Africa, the Middle East, Latin America and other countries and regions, the products are favored by Chinese and foreign users.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE