Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

S355N steel

Product Details

Product introduction

Steel Plate EN10025-3

S355N Steel Grade, Mechanical Properties, Chemical Composition, Grade Equivalent Standard: EN 10025-3 :2004 European standard for hot-rolled structural steel.

Technical data

EN10025-3 S275N

| Chemical composition % MAX | ||||||||||||

| C | Mn | Si | P | S | Nb | V | Al | Ti | Cr | Mo | N | |

| 0.20 | 0.45-1.60 | 0.45 | 0.035 | 0.03 | 0.06 | 0.07 | 0.015 | 0.06 | 0.35 | 0.13 | 0.017 | |

| Mechanical properties MIN | ||||||||||||

| Yield strength (Mpa) | Tensile strength (Mpa) | Elongation % | ||||||||||

| ≤16 | >16≤40 | >40≤63 | >63 ≤80 | >80≤100 | >100≤150 | >150≤200 | >200≤250 | >250≤400 | ≤100 | >100 ≤200 | >200≤250 | |

| 275 | 265 | 255 | 245 | 235 | 225 | 215 | 205 | - | 370-510 | 350-480 | 350-480 | 23 |

EN10025-3 S355N

| Chemical composition % MAX | ||||||||||||

| C | Mn | Si | P | S | Nb | V | Al | Ti | Cr | Mo | N | Ni |

| 0.20 | 0.85-1.75 | 0.55 | 0.035 | 0.03 | 0.06 | 0.14 | 0.015 | 0.06 | 0.35 | 0.13 | 0.017 | 0.55 |

| Mechanical properties MIN | ||||||||||||

| Yield strength (Mpa) | Tensile strength (Mpa) | Elongation % | ||||||||||

| ≤16 | >16≤40 | >40≤63 | >63 ≤80 | >80≤100 | >100≤150 | >150≤200 | >200≤250 | >250≤400 | ≤100 | >100 ≤200 | >200≤250 | |

| 355 | 345 | 335 | 325 | 315 | 295 | 285 | 275 | - | 470-630 | 450-600 | 450-600 | 21 |

EN10025-3 S275NL

| Chemical composition % MAX | ||||||||||||

| C | Mn | Si | P | S | Nb | V | Al | Ti | Cr | Mo | N | |

| 0.20 | 0.45-1.60 | 0.45 | 0.03 | 0.035 | 0.06 | 0.07 | 0.015 | 0.06 | 0.35 | 0.13 | 0.017 | |

| Mechanical properties MIN | ||||||||||||

| Yield strength (Mpa) | Tensile strength (Mpa) | Elongation % | ||||||||||

| ≤16 | >16≤40 | >40≤63 | >63 ≤80 | >80≤100 | >100≤150 | >150≤200 | >200≤250 | >250≤400 | ≤100 | >100 ≤200 | >200≤250 | |

| 275 | 265 | 255 | 245 | 235 | 225 | 215 | 205 | - | 370-510 | 350-480 | 350-480 | 23 |

EN10025-3 S420N

| Chemical composition % MAX | ||||||||||||

| C | Mn | Si | P | S | Nb | V | Al | Ti | Cr | Mo | N | Ni |

| 0.20 | 0.95-1.80 | 0.65 | 0.035 | 0.03 | 0.06 | 0.22 | 0.015 | 0.06 | 0.35 | 0.13 | 0.027 | 0.85 |

| Mechanical properties MIN | ||||||||||||

| Yield strength (Mpa) | Tensile strength (Mpa) | Elongation % | ||||||||||

| ≤16 | >16≤40 | >40≤63 | >63 ≤80 | >80≤100 | >100≤150 | >150≤200 | >200≤250 | >250≤400 | ≤100 | >100 ≤200 | >200≤250 | |

| 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 | - | 520-680 | 500-650 | 500-650 | 18 |

EN10025-3 S355NL

| Chemical composition % MAX | ||||||||||||

| C | Mn | Si | P | S | Nb | V | Al | Ti | Cr | Mo | N | Ni |

| 0.20 | 0.95-1.75 | 0.55 | 0.03 | 0.025 | 0.06 | 0.14 | 0.015 | 0.06 | 0.35 | 0.13 | 0.017 | 0.85 |

| Mechanical properties MIN | ||||||||||||

| Yield strength (Mpa) | Tensile strength (Mpa) | Elongation % | ||||||||||

| ≤16 | >16≤40 | >40≤63 | >63 ≤80 | >80≤100 | >100≤150 | >150≤200 | >200≤250 | >250≤400 | ≤100 | >100 ≤200 | >200≤250 | |

| 355 | 345 | 335 | 325 | 315 | 295 | 285 | 275 | - | 470-630 | 450-600 | 450-600 | 21 |

EN10025-3 S460N

| Chemical composition % MAX | ||||||||||||

| C | Mn | Si | P | S | Nb | V | Al | Ti | Cr | Mo | N | Ni |

| 0.22 | 0.95-1.80 | 0.55 | 0.035 | 0.03 | 0.06 | 0.22 | 0.015 | 0.06 | 0.35 | 0.13 | 0.027 | 0.85 |

| Mechanical properties MIN | ||||||||||||

| Yield strength (Mpa) | Tensile strength (Mpa) | Elongation % | ||||||||||

| ≤16 | >16≤40 | >40≤63 | >63 ≤80 | >80≤100 | >100≤150 | >150≤200 | >200≤250 | >250≤400 | ≤100 | >100 ≤200 | >200≤250 | |

| 460 | 440 | 430 | 410 | 400 | 380 | 370 | 275 | - | 540-720 | 530-710 | ~ | 17 |

EN10025-3 S420NL

| Chemical composition % MAX | ||||||||||||

| C | Mn | Si | P | S | Nb | V | Al | Ti | Cr | Mo | N | Ni |

| 0.22 | 0.95-1.80 | 0.65 | 0.03 | 0.025 | 0.06 | 0.22 | 0.015 | 0.06 | 0.35 | 0.13 | 0.027 | 0.85 |

| Mechanical properties MIN | ||||||||||||

| Yield strength (Mpa) | Tensile strength (Mpa) | Elongation % | ||||||||||

| ≤16 | >16≤40 | >40≤63 | >63 ≤80 | >80≤100 | >100≤150 | >150≤200 | >200≤250 | >250≤400 | ≤100 | >100 ≤200 | >200≤250 | |

| 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 | - | 520-680 | 500-650 | 500-650 | 18 |

EN10025-3 S460NL

| Chemical composition % MAX | ||||||||||||

| C | Mn | Si | P | S | Nb | V | Al | Ti | Cr | Mo | N | Ni |

| 0.22 | 0.95-1.80 | 0.65 | 0.03 | 0.025 | 0.06 | 0.22 | 0.015 | 0.06 | 0.35 | 0.13 | 0.027 | 0.85 |

| Mechanical properties MIN | ||||||||||||

| Yield strength (Mpa) | Tensile strength (Mpa) | Elongation % | ||||||||||

| ≤16 | >16≤40 | >40≤63 | >63 ≤80 | >80≤100 | >100≤150 | >150≤200 | >200≤250 | >250≤400 | ≤100 | >100 ≤200 | >200≤250 | |

| 460 | 440 | 430 | 410 | 400 | 380 | 370 | 275 | - | 540-720 | 530-710 | - | 17 |

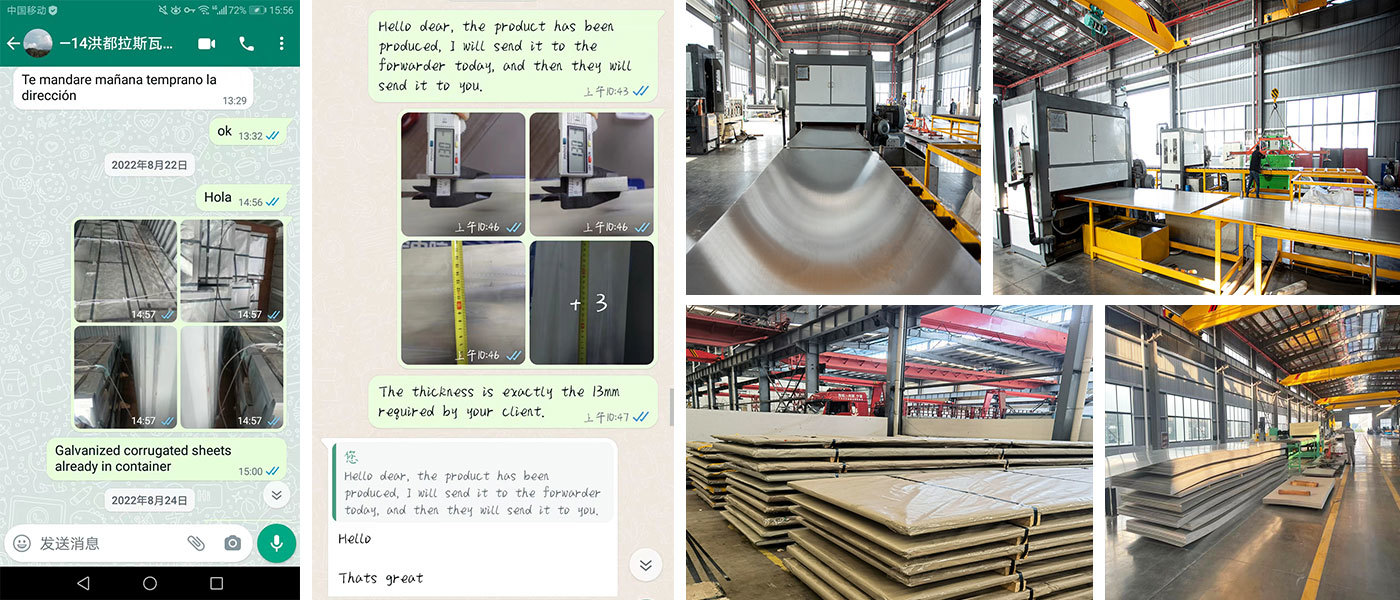

CUSTOMER TRANSACTION

Always adhere to the tenet of high quality, low cost, fast pace and excellent service. Shandong Chengshun Metal Materials Co., Ltd. is willing to cooperate sincerely with friends from all walks of life at home and abroad for common development.

STORAGE VIDEO

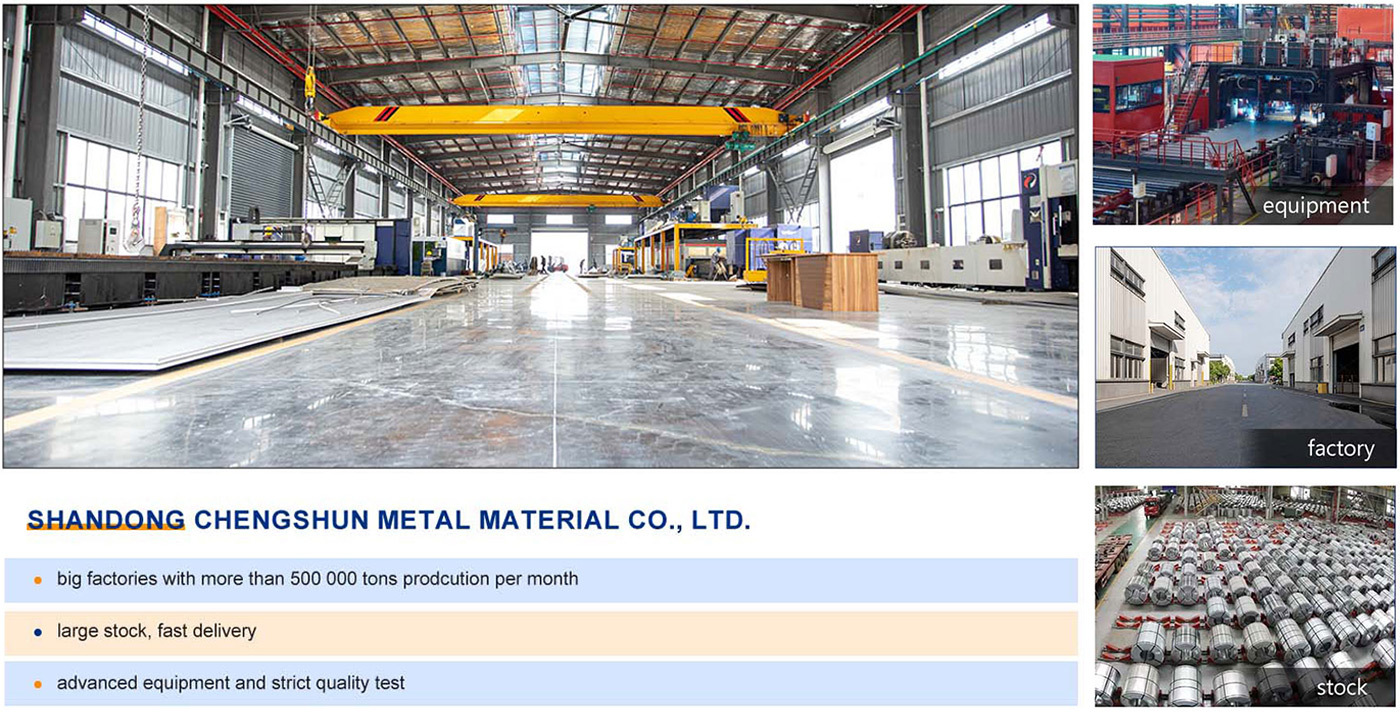

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

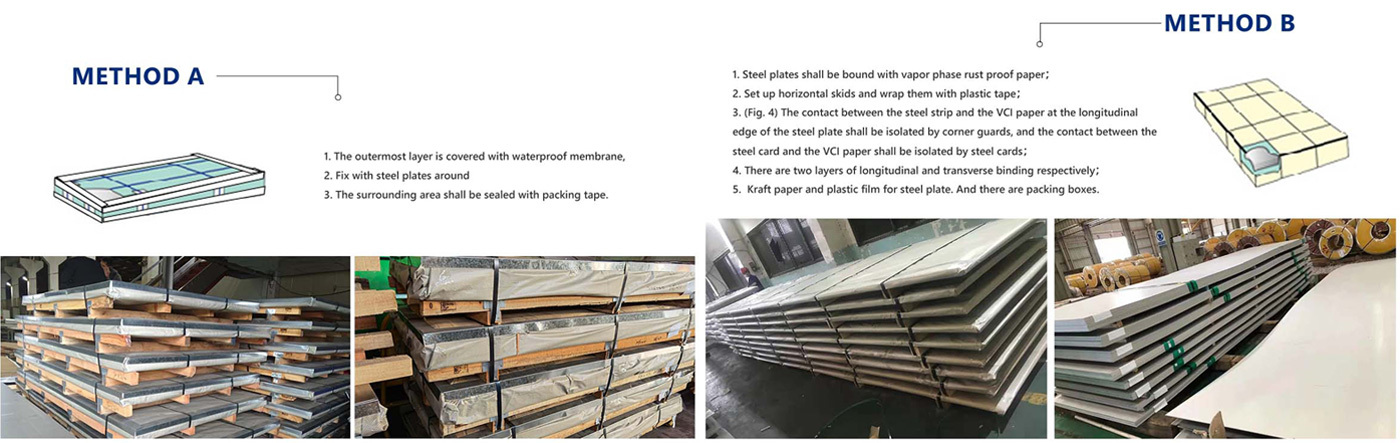

Packing and shipping

Mainly exported to Europe, Southeast Asia, South Africa, the Middle East, Latin America and other countries and regions, the products are favored by Chinese and foreign users.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE