Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Oil pipe line API 5L ASTM A106 A53 seamless steel pipe

which can be used as structural steel or for low-pressure pipelines.

ASTM A53 (ASME SA53) carbon steel pipe is a specification that covers seamless and

welded black and hot-dipped galvanized steel pipe

in NPS 1/8″ to NPS 26.

Product Details

Product introduction

ASTM A53 Grade B Seamless is our most popular product under this specification and A53 pipe is commonly dual certified to A106 B Seamless pipe.

ASTM A53 Grade B is the material under the American steel pipe standard, API 5L Gr.B is also the American standard material, A53 GR.B ERW refers to the electric resistance welded steel pipe of A53 GR.B; API 5L GR.B Welded refers to the material Welded steel pipe of API 5L GR.B.

Chemical Properties %

| / | Grade | C, max |

Mn, max |

P, max |

S, max |

Cu*, max |

Ni*, max |

Cr*, max |

Mo*, max |

V*, max |

| Type S (Seamless) | A | 0.25 | 0.95 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| B | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | |

| Type E (Electric-resistance Welded) | A | 0.25 | 0.95 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| B | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | |

| Type F (Furnace-welded) | A | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

*The total composition for these five elements shall not exceed 1.00%

Mechanical Properties

| Grade A | Grade B | |

| Tensile Strength, min., psi, (MPa) | 48,000 (330) | 60,000 (415) |

| Yield Strength, min., psi, (MPa) | 30,000 (205) | 35,000 (240) |

(Note: This is summarized information from ASME Specification A53. Please refer to the specific Standard or Specification or contact us for more details.)

ASTM A53 seamless steel pipe is an American standard brand. A53-F corresponds to China's Q235 material, A53-A corresponds to China's No. 10 material, and A53-B corresponds to China's No. 20 material.

Production process

Seamless steel pipe manufacturing process is divided into hot-rolled and cold seamless pipe.

1. Production process of hot-rolled seamless steel pipe: tube billet → heating → perforation → three-roller/cross-rolling & continuous rolling → de-pipe → sizing → cooling → straightening → hydraulic test → marking → seamless steel pipe with leverage effect detected.

2. Production process of cold drawn seamless steel tubes: tube blank → heating → perforation → heading → annealing → pickling → oiling → multiple cold drawing → blank tube → heat treatment → straightening → hydraulic test → marking → storage.

Applications

1. Construction: the pipeline underneath, the groundwater, and the hot water transportation.

2. Mechanical processing, bearing sleeves, processing machinery parts, etc.

3. Electrical: Gas delivery, Hydroelectric power fluid pipeline

4. Anti-static tubes for wind power plants, etc.

Technical data

| Product name | Material | Standard | Size(mm) | Application |

| Low temperature tube | 16MnDG 10MnDG 09DG 09Mn2VDG 06Ni3MoDG ASTM A333 |

GB/T18984- 2003 ASTM A333 | OD:8-1240* WT:1-200 |

Apply to - 45 ℃ ~ 195 ℃ low temperature pressure vessel and low temperature heat exchanger pipe |

| High-pressure boiler tube | 20G ASTMA106B ASTMA210A ST45.8-III |

GB5310-1995 ASTM SA106 ASTM SA210 DIN17175-79 |

OD:8-1240* WT:1-200 |

Suitable for manufacturing high pressure boiler tube, header, steam pipe, etc |

| Petroleum cracking tube | 10 20 |

GB9948-2006 | OD: 8-630* WT:1-60 |

Used in oil refinery furnace tube, heat exchanger tube |

| Low medium pressure boiler tube | 10# 20# 16Mn,Q345 |

GB3087-2008 | OD:8-1240* WT:1-200 |

Suitable for manufacturing various structure of low and medium pressure boiler and locomotive boiler |

| General structure of the tube | 10#,20#,45#,27SiMn ASTM A53A,B 16Mn,Q345 |

GB/T8162- 2008 GB/T17396- 1998 ASTM A53 |

OD:8-1240* WT:1-200 |

Apply to the general structure, engineering support, mechanical processing, etc |

| Oil casing | J55,K55,N80,L80 C90,C95,P110 |

API SPEC 5CT ISO11960 |

OD:60-508* WT:4.24-16.13 |

Used for extraction of oil or gas in oil Wells casing, used in oil and gas well sidewall |

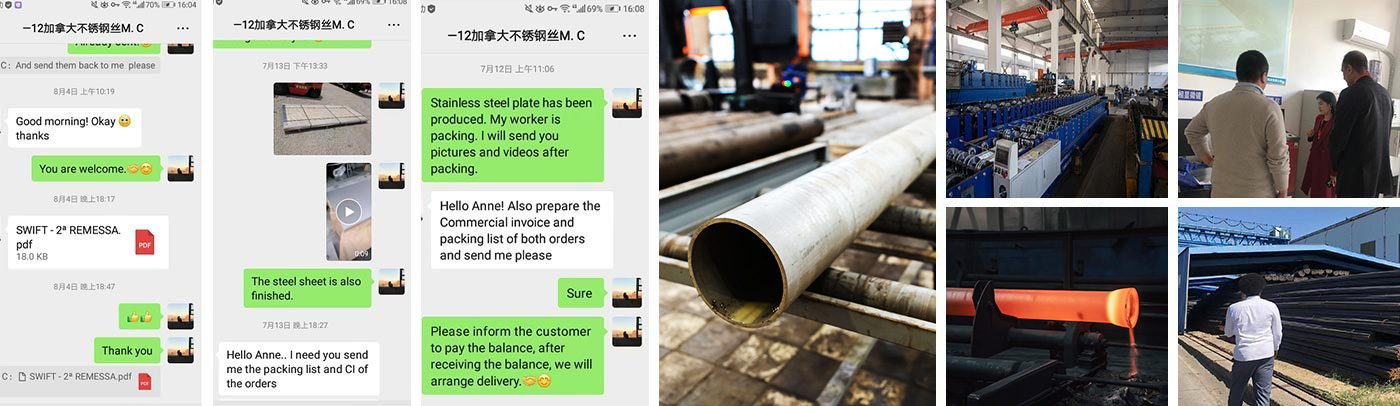

CUSTOMER TRANSACTION

Always adhere to the tenet of high quality, low cost, fast pace and excellent service. Shandong Chengshun Metal Materials Co., Ltd. is willing to cooperate sincerely with friends from all walks of life at home and abroad for common development.

STORAGE VIDEO

Factory Appearance

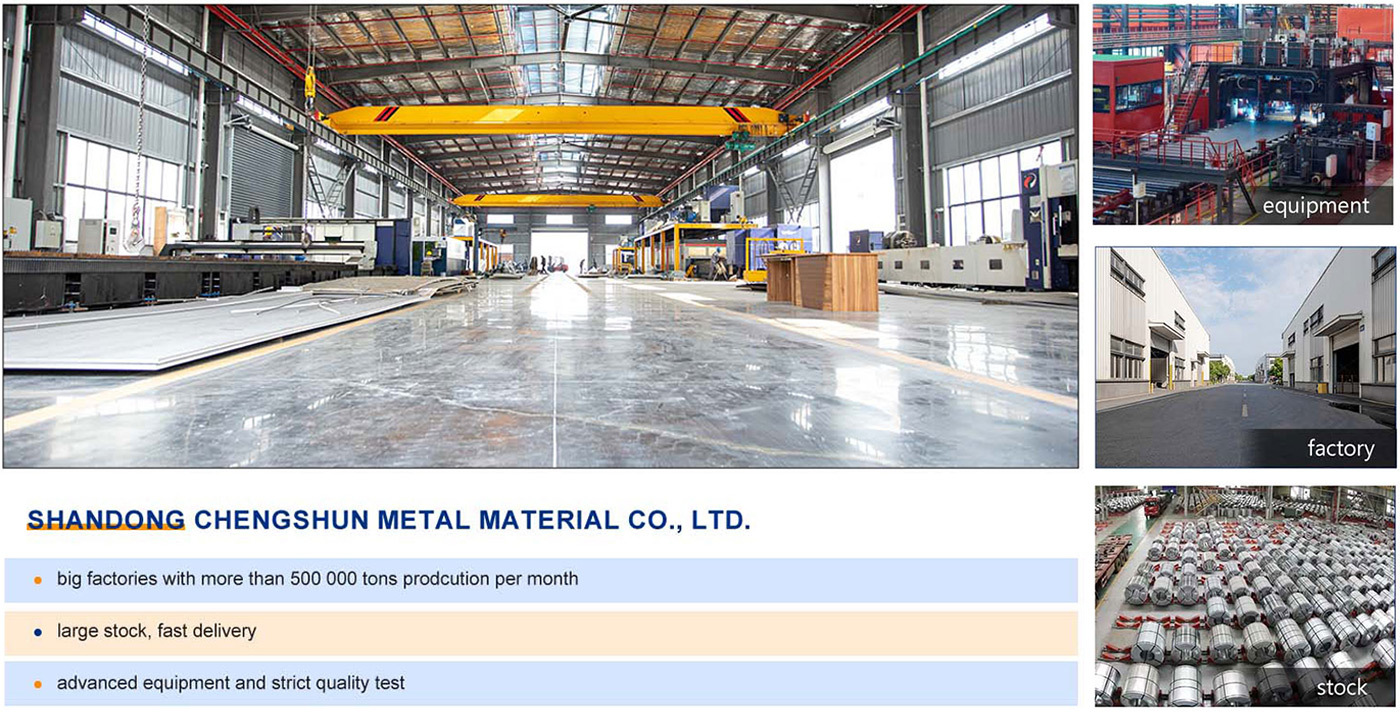

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE