Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

410HT Stainless Steel Sheet

Product Details

Product Information

Alloy 410 HT is the basic, general purpose, heat treated version of Type 410. It is a martensitic type, used for general purpose, where corrosion is not severe. Alloy 410 contains a minimum of 11.5% chromium which is just sufficient enough to demonstrate corrosion resistance properties in mild atmospheres, steam, and many mild chemical environments.

Product Details

Chemical Properties:

| C | Mn | Si | P | S | Cr | Ni | |

|---|---|---|---|---|---|---|---|

| 410HT | 0.15 max | 1.00 max | 1.00 max | 0.04 max | 0.03 max | min: 11.5 max: 13.5 |

0.50 max |

Mechanical Properties:

| Grade | Tensile Strength ksi (MPa) min | Yield Strength 0.2% offset ksi (MPa) min | Elongation (% in 50mm) min | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 410HT | 65 (450) | 30 (205) | 20 |

Standards:

- ASTM/ASME: UNS S41000

- EURONORM: FeMi35Cr20Cu4Mo2

- DIN: 2.4660

Corrosion Resistance:

- Good corrosion resistance to atmospheric corrosion, potable water, and to mildly corrosive environments

- Its exposure to everyday activities (sports, food preparation) is generally satisfactory when proper cleaning is performed after exposure to use

- Good corrosion resistance to low concentrations of mild organic and mineral acids

Welding Characteristics

- Readily welded by all standard methods

- To reduce the risk of cracking, it is suggested to pre-heat the work piece to 350 to 400oF (177 to 204oC)

- Post weld annealing is recommended to retain maximum ductility

Heat Treatment

- The proper hot work range is 2000 to 2200oF (1093 to 1204oC)

- Do not work this material below 1650oF (899oC)

Mechanical Properties of Heat Treated 410:

| Heat Treatment | T410 (0.14%C) Hardened 1800°F (982°C) | ||

|---|---|---|---|

| Rockwell Hardness | 0.2% YS, Ksi (MPa) | UTS, Ksi (MPa) | |

| Annealed* | 81 HRB | 45.4 (313) | 80.4 (554) |

| Hardened & Tempered 400°F (204°C) | 43 HRC | 156.1 (1076) | 202.9 (1399) |

| Hardened & Tempered 550°F (288°C) | 40 HRC | 148.3 (1022) | 187.0 (1289) |

| Hardened & Tempered 600°F (316°C) | 40 HRC | 148.8 (1026) | 186.1 (1283) |

| Hardened & Tempered 800°F (427°C) | 41 HRC | 132.9 (916) | 188.5 (1300) |

| Hardened & Tempered 900°F (482°C) | 41 HRC | 122.6 (845) | 154.3 (1063) |

| Hardened & Tempered 1000°F (538°C) | 35 HRC | 127.9 (882) | 154.3 (1063) |

| Hardened & Tempered 1200°F (649°C) | 98 HRB | 85.5 (589) | 111.2 (767) |

Applications:

Applications requiring moderate corrosion resistance and high mechanical properties are ideal for Alloy 410HT. Examples of applications that frequently used Alloy 410HT include:

- Cutlery

- Steam and gas turbine blades

- Kitchen utensils

- Bolts, nuts, screws

- Pump and valve parts and shafts

- Mine ladder rugs

- Dental and surgical instruments

- Nozzles

- Hardened steel balls and seats for oil well pumps

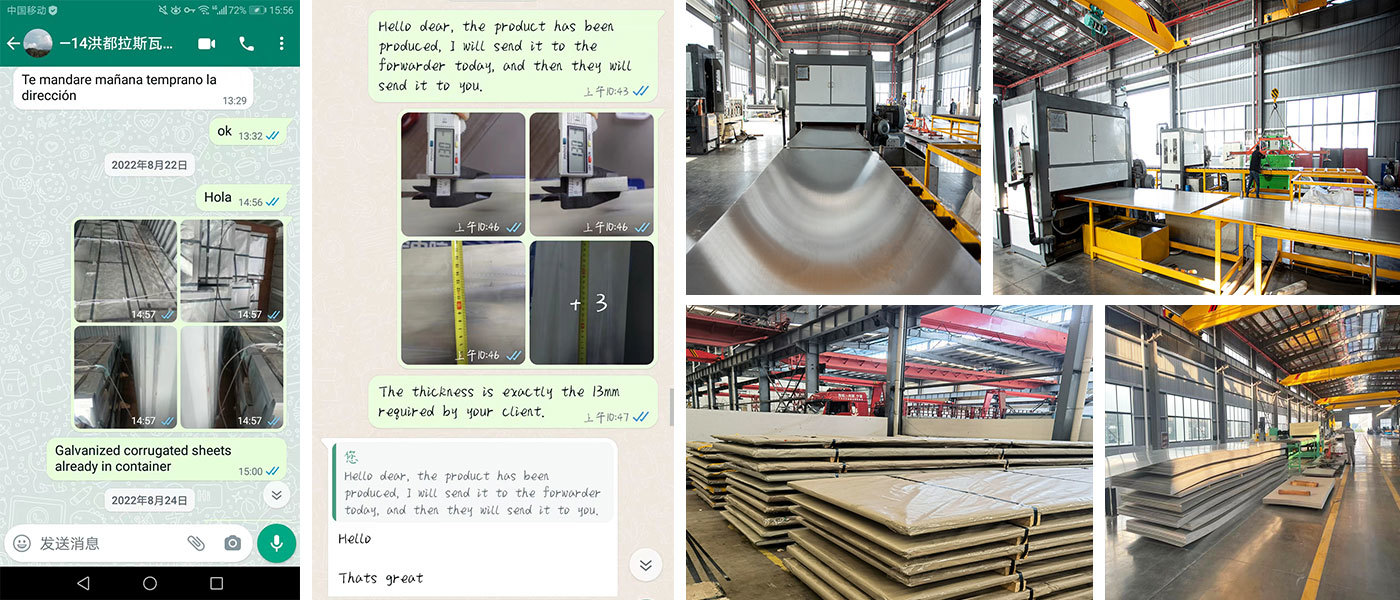

CUSTOMER TRANSACTION

Always adhere to the tenet of high quality, low cost, fast pace and excellent service. Shandong Chengshun Metal Materials Co., Ltd. is willing to cooperate sincerely with friends from all walks of life at home and abroad for common development.

STORAGE VIDEO

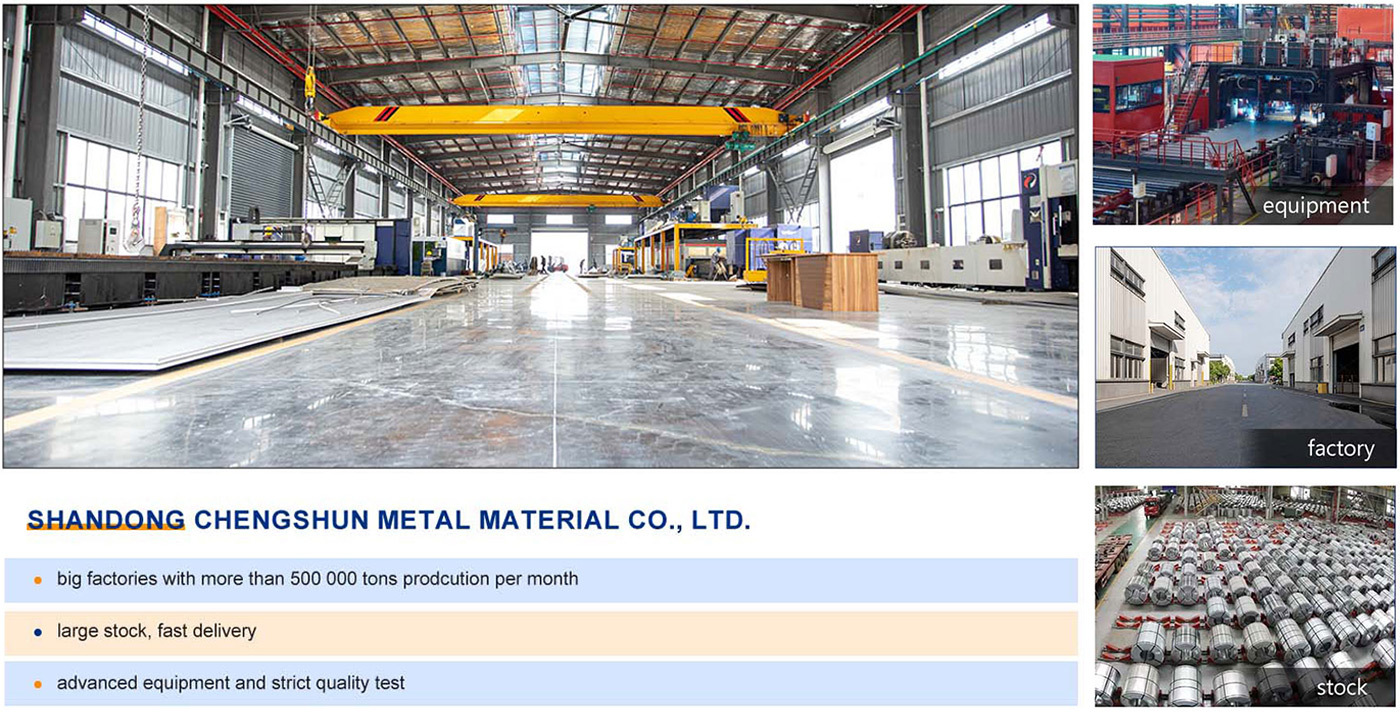

Factory Appearance

Shandong Chengshun Metal Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality.

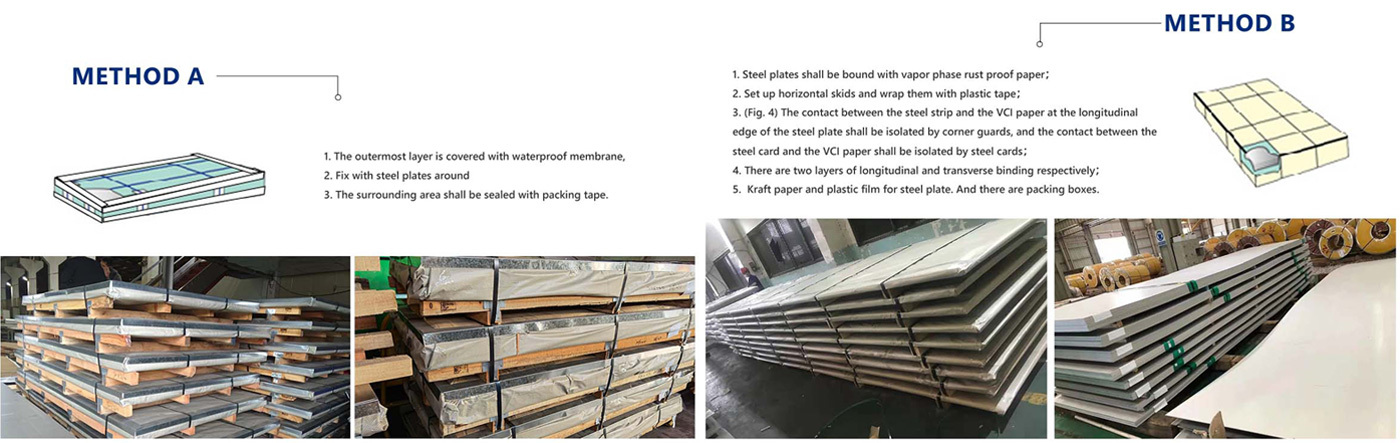

Packing and shipping

Mainly exported to Europe, Southeast Asia, South Africa, the Middle East, Latin America and other countries and regions, the products are favored by Chinese and foreign users.

product display

Application field

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

PRODUCTION WORKSHOP

RELATED PRODUCTS

GET A FREE QUOTE